Introduced: 2025

ScaleTrains.com's "Rivet Counter" GP30 models are available either DCC-Ready or with a factory-installed ESU sound decoder. Each model has its own unique paint and detailing package (based on the prototype in question).

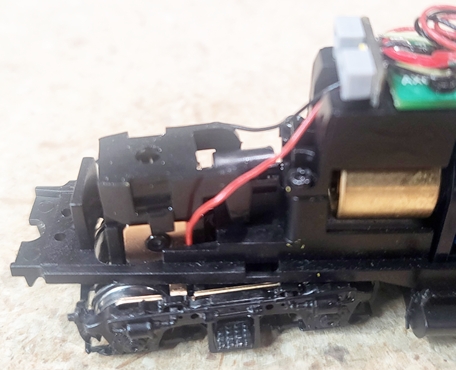

Internally, these models are quite similar to STC's previous diesel releases. The chassis consists of a metal base with a metal bracket screwed to the top (holding the motor and drivetrain in place). The motor is an open-sided 5-poler with skew-winding. Each motorshaft is equipped with a flywheel (although they are somewhat ineffective, as these locos start and stop on a dime without the aid of a decoder). Plastic driveshafts seat inside of the flywheels and connect to notched cups on the truck towers. Short metal shafts connect the cups to the brass worm gears mounted inside the truck towers.

The motherboard is screwed to the top bracket and receives current from the trucks by way of four wires. Separately wired boards fore and aft of the main PC board provide bright white LED lighting for the forward numberboards, headlight, rear numberboards, and backup light. The headlight and backup light are directional whereas the numberboard lighting is constant (always on). Additional wires run from the main PC board to the motor and (for DCC-Sound models) to a speaker mounted inside the fuel tank. The decoder interface on the DCC-Ready motherboard is "E24".

All four axles are geared and all gearing (apart from the worms) is plastic. The wheels are blackened and low-profile (no problems on Atlas Code-55 track). There are no traction tires. STC's MTL-style automatic couplers are mounted to the chassis. The plastic fuel tank is screwed to the bottom of the chassis. Holes in the fuel tank are provided for the speaker. For the DCC Sound models, the speaker is seated inside of a pocket in the chassis.

All eight wheels provide pickup by way of axle-end wipers (the axle ends seat inside of holes in said wipers). Wires soldered to the axle wipers transfer current to the motherboard. As pictured, the trucks are a rather complex assembly and removing them would likely be a rather daunting proposition. An extension on the top of the plastic truck tower assembly holds the trucks inside the chassis, so I guess you would basically have to completely disassemble the truck towers and disconnect the driveshafts in order to get the trucks off.

Shell detailing is beyond amazing, including see-through fans -

These are superb runners - smooth, whisper quiet, excellent slow-speed creep and a realistic top-end speed. Mine ran well right out of the box, so pre-emptive wheels cleaning doesn't appear to be required. Mine can creep through insulated frog turnouts at very slow speeds, so pickup is flawless. Pulling power is adequate (although just barely), with mine able to handle about 25 assorted 40' freight cars through curves on level track (any more than that and the wheels are slipping). I didn't have any problems with the wheels derailing (even on 9.75" radius curves). The sound isn't bad, although perhaps just a bit thin and tinny sounding to my ear (which is pretty much my opinion of most N scale sound installations these days).

One minor annoyance I have with the ESU decoder is the whole protracted "start up" sequence the locomotive goes through when moving from a dead stop (basically the locomotive sits there making various noises for 4-5 seconds before it starts moving). All very prototypical I'm sure, but not something I really want to have to deal with (particularly when MU'ing an STC loco with some other brand of loco that just wants to go). Changing CV124 from 4 to 16 eliminates this behavior. Also, the default behavior is for sound to be off when you first put the locomotive on the rails (with F8 then turning it on). If you want the reverse of that (sound comes on when you put the loco on the rails and turns off with F8), set CV31=16, CV32=2, and CV419=32.

For the DCC-equipped models, some CV tweaking may be necessary in order to achieve optimum performance. Performing a CV54 "BEMF auto tune" (set CV54 to 0 and then hit F1) should smooth out most performance issues. Another option would be to lower the value of CV56 (default setting is 255) to reduce the amount of BEMF influence over the speed. Yet another option to adjust BEMF would be to increase the value of CV52 from its default setting of 15. Between those three CVs, it should be possible to address any BEMF-related glitches that might arise.

Prototype -

First introduced in 1961, the GP30 would become one of the most common locomotives on the rails for the next two decades.

Features -

- All-new model

- Era: Mid-1960s

- Fully-assembled

- Multiple road numbers

- Directional LED headlights

- Class lights (non-operating)

- Printed and LED-illuminated cab and rear number boards

- Front and rear multiple unit (MU) hose catch boxes

- 4-hose multiple unit (MU) hose clusters with silver gladhands

- Body mounted knuckle couplers; Micro-Trains compatible (coupler box accepts Micro-Trains 1015/1016 couplers without modification)

- Factory-applied wire grab irons, windshield wipers, trainline hoses with silver gladhands, air tanks and more

- Motor with 5-pole skew wound armature

- Dual flywheels

- All-wheel drive

- All-wheel electrical pick-up

- Printing and lettering legible even under magnification

- Operates on Code 55 and 80 rail

- Packaging safely stores model

- Minimum radius: 9 3/4"

- Recommended radius: 11"

- DCC ready with E24 connector

DCC Features -

- ESU LokSound 5 DCC & Sound decoder with "Full Throttle"

- Single cube-type speaker

- EMD 16 Cylinder 567D3 prime mover

- Operates on both DC and DCC layouts

Shell Removal -

To remove the shell, you first have to unscrew and remove the couplers (which are going to fall apart in the process, so have fun with that). Once the couplers are out of the way, the shell should slide up and off readily. Be mindful of the skinny plastic sand lines when putting the shell back on as they are easily damaged.

Grade: A