ET44C4 -

ET44AH -

ET44AC -

C45AH -

ET44C4 -

ET44AH -

ET44AC -

C45AH -

Introduced: 2018

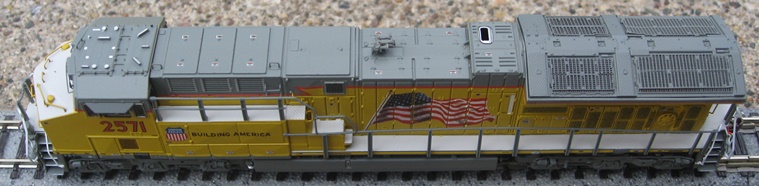

ScaleTrains.com's line of GE Tier 4 GEVo models was released under their high end "Rivet Counter" line. They are available either DCC-Ready or equipped with a factory-installed ESU LokSound DCC-Sound decoder and speaker. Each model has its own unique paint and detailing package (based on the prototype in question). As pictured below, the level of fine detailing on these models is pretty much off the charts -

About my only complaint (at least with the UP version) is that the paint on the nose and the walkways looks very wrong. It's very nearly white, when it should in fact be the same (or similar) gray found elsewhere on the model. STC got it right on their HO version, so I don't what happened here.

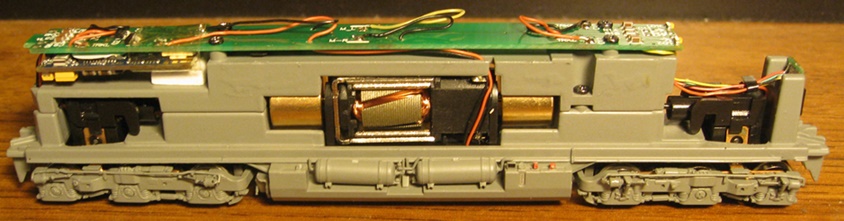

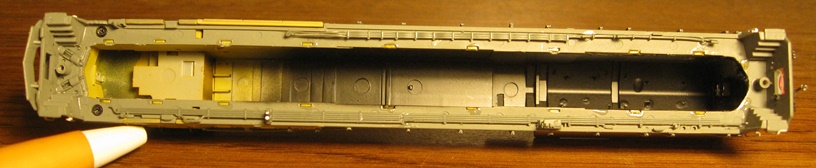

Internally, these models are quite a departure from the standard split-frame design found in most modern N scale diesels (from the likes of Atlas, Kato, et al) -

The chassis consists of a metal base with a metal bracket screwed to the top (holding the motor and drivetrain in place). The motor is an open-sided 5-poler with skew-winding. Each motorshaft is equipped with a flywheel (although they are somewhat ineffective, as these locos start and stop on a dime without the aid of a decoder). Plastic driveshafts seat inside of the flywheels and connect to notched cups on the truck towers. Short metal shafts connect the cups to the brass worm gears mounted inside the truck towers.

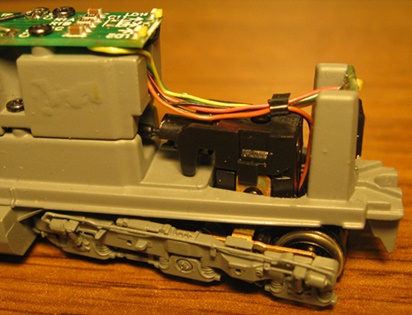

The lightboard is screwed to the top bracket and receives current from the trucks by way of four wires. Directional lighting for the backup light and forward numberboards is provided by LEDs on the back and front of the lightboard. A separate LED board for the headlight and ditchlights is wired up on the front of the chassis. The lighting is white and very bright. Additional wires run from the lightboard to the motor and (for DCC-Sound models) to a speaker mounted inside the fuel tank. The decoder interface on the DCC-Ready lightboard is something called "Next 18" (or NEM662). This is evidently something new in the world of DCC connectivity as I don't recall ever having coming across it before. A small piece of white foam insulation sitting between the decoder and the chassis helps to keep the decoder from popping loose when putting the shell on.

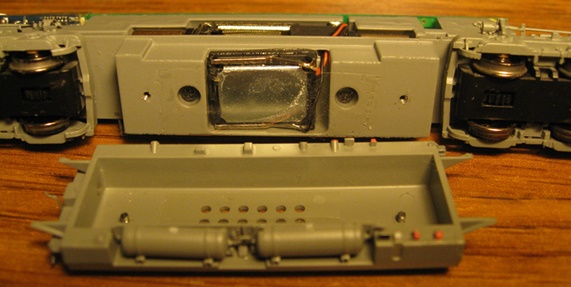

All six axles are geared and all gearing (apart from the worms) is plastic. The wheels are blackened and low-profile (no problems on Atlas Code-55 track). There are no traction tires. STC "E Type" automatic couplers are mounted to the chassis. Note that said couplers do not come with any sort of metal trip pin, so I guess magnetic uncoupling is not an option. At this point I'm not sure what the replacement options might be, but I've read that MTL 1015's are definitely a no-go.

The plastic fuel tank is screwed to the bottom of the chassis. Holes are provided for the speaker that comes with the DCC-Sound models (although I'm not really sure why - the speaker appears to be installed such that sound projects upward rather than downward).

All 12 wheels provide pickup by way of axle-end wipers (the axle ends seat inside of holes in said wipers). Wires soldered to the axle wipers transfer current to the lightboard. As pictured, the trucks are a rather complex assembly and removing them would likely be a rather daunting proposition. An extension on the top of the plastic truck tower assembly holds the trucks inside the chassis, and so I guess you would basically have to completely disassemble the truck towers and disconnect the driveshafts in order to get the trucks off. In other words, let's all pray that those solders on the wiper wires never fail. Removing the trucks in order to get at them looks like a whole lot of not much fun.

Shell removal is very simple - just unscrew and remove the couplers. After that, the shell should readily slide up and off. Note that the various shell components (hood, cab, sidesill, etc) appear to be glued together. So, if you're a repainter.... well, good luck with all that.

Overall performance on these models is impressive. For starters, my DCC-Sound version didn't require any sort of preemptive wheel-cleaning in order to get it to run properly. Unlike most other sound-equipped models I've tested lately, this one ran perfectly right out of the box. Throttle response is smooth and it runs whisper quiet at all speeds. Slow speed creep (at speed step 1) is suitably sloth-esque and the top-end speed is reasonable and realistic. Pulling power is respectable, with mine able to handle around 28 assorted 50' freight cars through curves on level track (any more than that and the wheels start slipping). I didn't have any problems with any of the wheels derailing (even on curves as sharp as 9.75" radius). Pickup is flawless, with mine able to creep through insulated-frog turnouts at yard speeds without so much as a hiccup.

In regards to pickup, I did find that my loco started to get a bit balky after a few hours of run time (IE, hello headlight flicker). My solution here was to give the wheels a good cleaning (god knows what they might've picked up from my track). I also added a bit of conductalube to the axle ends just to make sure I was getting good conductivity there. After all that, it was running fine once again.

Speaker volume on the DCC-Sound models is damned near perfect for me (IE barely audible), which probably means that a lot of people (especially those who like to run their locos in crowded/noisy environs) are not going to be too happy with it. Unfortunately, increasing the master volume (CV69) from the stock setting of 128 to something higher (180 seems to be the max) doesn't seem to make a huge difference (at least to my ear).

One minor annoyance I have with the ESU decoder is the whole protracted "start up" sequence the locomotive goes through when moving from a dead stop (basically the locomotive sits there making various noises for 4-5 seconds before it starts moving). All very prototypical I'm sure, but not something I really want to have to deal with (particularly when MU'ing an STC loco with some other brand of loco that just wants to go). Setting CV124 to 16 eliminates this behavior. Also, the default behavior is for sound to be off when you first put the locomotive on the rails (with F8 then turning it on). If you want the reverse of that (sound comes on when you put the loco on the rails and turns off with F8), set CV31=16, CV32=2, and CV419=32.

Setting aside the minor quibbles, these are sensational looking models that perform admirably well. And given the level of fine detailing here, I think it's safe to say that the N scale bar has definitely been raised.

Note - the decoders on the DCC-Sound models do not use default (factory) CV settings. IE, if you ever perform a decoder reset, your locomotive will no longer behave like it did when it was new. Unfortunately, the included manual does not appear to provide a list of these non-default CV settings, so I guess you'd need to contact STC directly if you ever need reprogram them.

Prototype -

Introduced in 2012, General Electric's Tier 4 GEVo Series represents the latest in diesel-electric locomotive technology. The GE Tier 4 GEVo is designed to meet increasingly stringent Environmental Protection Agency (EPA) emissions regulations. The EPA Tier emissions standards are a series, or Tiers, of allowable emissions levels based upon a locomotive's date of manufacture. The highest and most stringent tier level, Tier 4, sets maximum allowable NOx and hydrocarbon emissions levels for locomotives built for domestic use 2015 onward.

While similar in appearance to previous GE GEVo designs, the Tier 4 models featured a longer frame compared to their predecessors. This allows for a larger radiator cab (GE refers to the various sections of the long hood as cabs), and a "hump" over the engine cab for advanced exhaust treatment equipment. Initially, a boxy housing filled the entire roofline on the blue-painted field test/demonstrator units. Due to changes in treatment equipment and clearance issues, the "hump" would decrease in size and shape into a boxy compartment around the exhaust on initial production units. This culminated in an angled compartment surrounding the exhaust manifold on the latest production versions (2016+). Despite boxier engine cab rooflines and a radically styled radiator cab, the basic Tier 4 design shares a family appearance with GE safety cab-equipped units going back to the DASH-9s of the 1990s. It even includes the same 12-cylinder GEVo-12 series prime mover and 4,400hp as its predecessor model.

The Tier 4 units have proven to be popular with the major railroads including BNSF Railway, Canadian National, CSX Transportation, Norfolk Southern, and Union Pacific. While GE has settled on a basic carbody design to keep production costs down, there are notable variations and detail differences due to customer specifications. With many units built for railroads across the US and in Canada, the Tier 4 GEVo can be seen operating nationwide in a variety of assignments.

Features -

- Fully assembled

- Six different road numbers per model

- Directional LED headlights

- Printed and LED lit numberboards

- Tread plate on walkways

- Factory-applied wire grab irons, snowplow, spare knuckles, trainline hoses, 3-hose MU clusters, uncoupling levers, windshield wipers, mirrors, sunshades,

air tanks, brake wheel and more

- Body mounted ScaleTrains.com plastic semi-scale E Type knuckle couplers

- All-wheel drive

- All-wheel electrical pick-up

- Dual flywheels

- Motor with 5-pole skew-wound armature

- Printing and lettering legible under magnification

- Operates on Code 55 and Code 80 rail

- Durable packaging safely stores model

- Minimum Radius: 9.75"

- Recommended Radius: 11"

DCC-Sound Model Features -

- ESU-LokSound Next18 Select Micro DCC and sound decoder with Full Throttle

- Sugar cube type speaker

- Accurate GEVO-12 prime mover and auxiliary sounds, horn, bell, and more

- Operates on both DC and DCC layouts

DCC-Ready Model Features -

- "Next 18" DCC connector

- Operates on DC layouts

Grade: A