Operator C44-9W -

Operator C44-9W -

Introduced: 2019 (C44-9W) and 2024 (AC4400CW)

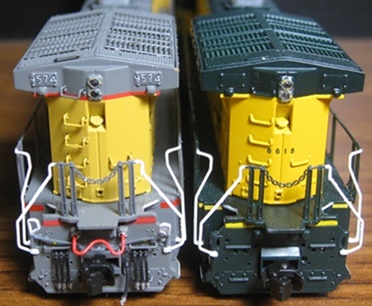

ScaleTrains.com's line of Dash 9 models was released under both their high end "Rivet Counter" label and their "Operator" label. They are available either DCC-Ready or with a factory-installed ESU decoder (either sound or non-sound). Each Rivet Counter model has its own unique paint and detailing package (based on the prototype in question). Operator models share a common cab and long hood configuration and cost about 20% less than the Rivet Counter models. The main difference between the two is that the Rivet Counter models have dozens of separate / press-fit detail parts (handgrabs and whatnot) whereas said details are simply molded into the shell on the Operator models. Also, all of the details come preinstalled on the Rivet Counter models (as opposed to the Operator models where the snowplow, MU cables and cut levers are supplied as an ala carte "do it yourself" project). Lastly, DCC-Sound is not available on the Operator models.

ScaleTrains.com's AC4400CW models only come in "Rivet Counter" variants. They are available either DCC-Ready or with a factory-installed ESU sound decoder. As with the Dash 9's, each model has its own unique paint and detailing package (based on the prototype in question). The AC4400CW model shares the same basic chassis / mechanism as the earlier C44-9W model, so I'm reviewing both of them here.

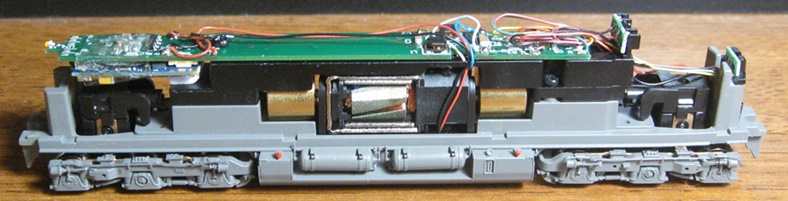

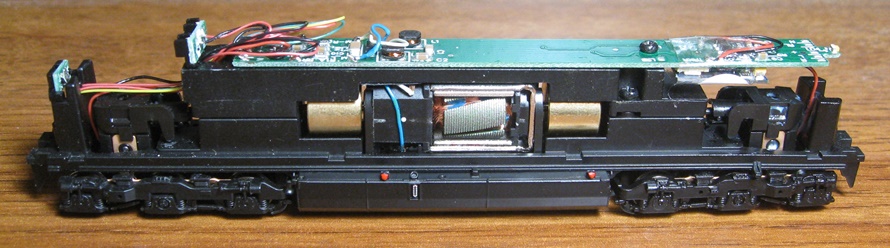

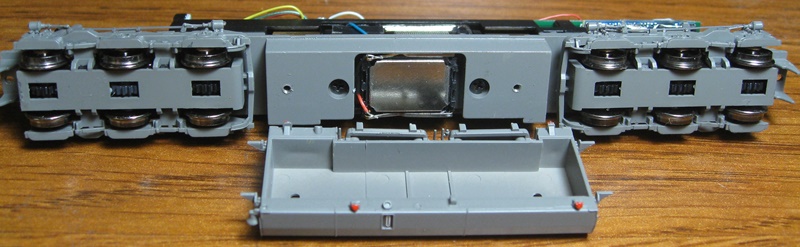

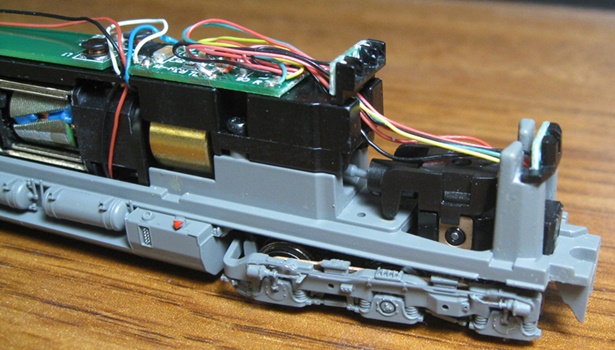

Internally, these models are quite similar to STC's previous diesel releases (GEVo and C39-8). The chassis consists of a metal base with a metal bracket screwed to the top (holding the motor and drivetrain in place). The motor is an open-sided 5-poler with skew-winding. Each motorshaft is equipped with a flywheel (although they are somewhat ineffective, as these locos start and stop on a dime without the aid of a decoder). Plastic driveshafts seat inside of the flywheels and connect to notched cups on the truck towers. Short metal shafts connect the cups to the brass worm gears mounted inside the truck towers.

The main PC board is screwed to the top bracket and receives current from the trucks by way of four wires. A trio of separately wired LED boards (for the forward numberboards, headlight and ditchlights) are mounted to the front of the chassis. An LED on the main PC board provides illumination for the backup light. The headlight and backup light are controlled by F0, whereas the ditchlights are controlled by F6. The headlight, backup light and ditchlights are directional, whereas the numberboard lighting is constant (always on). Note that the rear numberboards (for models so equipped) are not lit. The lighting is white and very bright. Additional wires run from the main PC board to the motor and (for DCC-Sound models) to a speaker mounted inside the fuel tank. The decoder interface on the DCC-Ready main board is "Next 18" (aka NEM662).

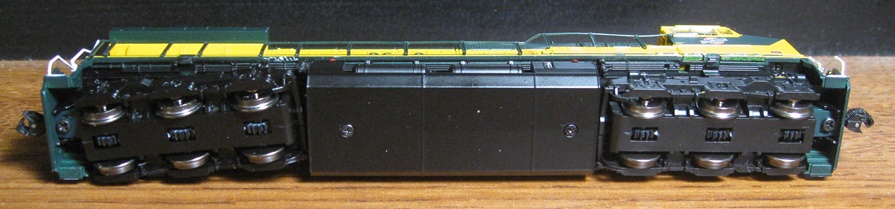

All six axles are geared and all gearing (apart from the worms) is plastic. The wheels are blackened and low-profile (no problems on Atlas Code-55 track). There are no traction tires. STC's McHenry-style automatic couplers are mounted to the chassis. Note that said couplers do not come with any sort of metal trip pin, so I guess magnetic uncoupling is not an option. These particular couplers appear to be an improvement over previous STC releases (at least insofar as they auto-couple much more readily than they've done in the past). STC states that the guts of their coupler boxes can be swapped out in favor of MTL 1015/1016 couplers (something I have never tried).

The plastic fuel tank is screwed to the bottom of the chassis. Holes are not provided for the speaker that comes with the DCC-Sound models (not really needed since the speaker is installed such that sound projects upward rather than downward).

All 12 wheels provide pickup by way of axle-end wipers (the axle ends seat inside of holes in said wipers). Wires soldered to the axle wipers transfer current to the main PC board. As pictured, the trucks are a rather complex assembly and removing them would likely be a rather daunting proposition. An extension on the top of the plastic truck tower assembly holds the trucks inside the chassis, and so I guess you would basically have to completely disassemble the truck towers and disconnect the driveshafts in order to get the trucks off.

Shell removal is very simple - just unscrew and remove the couplers. At that point, the shell should readily slide up and off. Note that the various shell components (hood, cab, sidesill, etc) appear to be glued together. So, if you're a repainter.... well, good luck with all that.

These are very nice runners - smooth, whisper quiet, excellent slow-speed creep and a realistic top-end speed. Mine ran well right out of the box, so pre-emptive wheels cleaning doesn't appear to be required. Mine can creep through insulated frog turnouts at very slow speeds, so pickup is flawless. Pulling power is outstanding with mine able to comfortably haul 43 assorted freight cars through curves on level track (and probably a whole lot more than that). I didn't have any problems with the wheels derailing (even on 9.75" radius curves). The sound is "OK", although maybe just a bit thin and tinny sounding to my ear (pretty much my opinion of all N scale sound installations these days).

One minor annoyance I have with the ESU decoder is the whole protracted "start up" sequence the locomotive goes through when moving from a dead stop (basically the locomotive sits there making various noises for 4-5 seconds before it starts moving). All very prototypical I'm sure, but not something I really want to have to deal with (particularly when MU'ing an STC loco with some other brand of loco that just wants to go). Changing CV124 from 4 to 16 eliminates this behavior. Also, the default behavior is for sound to be off when you first put the locomotive on the rails (with F8 then turning it on). If you want the reverse of that (sound comes on when you put the loco on the rails and turns off with F8), set CV31=16, CV32=2, and CV419=32.

For the DCC-equipped models, some CV tweaking may be necessary in order to achieve optimum performance. Out of the box, mine exhibited a very slight stutter at speed step 1 (IE, it wouldn't maintain a consistant speed). So, I performed a CV54 "BEMF auto tune" (set CV54 to 0 and then hit F1), which smoothed things right out. Another option would be to lower the value of CV56 (default setting is 255) to reduce the amount of BEMF influence over the speed. Yet another option to adjust BEMF would be to increase the value of CV52 from its default setting of 15. Between those three CVs, it should be possible to address any BEMF-related glitches that might arise. But overall these are terrific looking models that run extremely well.

C44-9W Features -

- Operating deck or pilot-mounted LED ditch lights

- Five different cab styles - "Gullwing with three side windows, Gullwing with four side windows, Standard safety cab with low headlight, Standard safety cab

with high headlight, Spartan cab with high headlight (C40-9)

- Four step or five step stepwells

- Narrow or wide profile end handrails

- Dayton Phoenix (DPG) Model 280620 or Motive Equipment (MEI) ME7000 HVAC Units

- Early or late (tri-fold power assembly access doors) engine cab profile

- Early flanged or late non-flanged exhaust stack housing

- Low or high rear sand filler

- GE nub pattern walkway tread

- Accurately profiled frame with separately applied plumbing and cabling

- Factory-applied detail parts: wire grab irons, snowplow, trainline hoses, 3-hose MU clusters, MU cable, uncoupling levers, windshield wipers, mirrors, sunshades, air tanks, fuel

tank mounted bell, brake wheel, exhaust stack, and more

- Nose door with window

- Detailed cab interior with floor, rear wall, seats, and controls

- Tinted cab side windows

- Bathtub exhaust silencer

- 5,000 gallon fuel tank

- GE Hi-Ad trucks with separately applied brake cylinders and air plumbing

Common Features -

- Fully-assembled

- Up to six different road numbers

- Printed and LED lighted number boards

- Semi-scale Type E knuckle couplers - Micro-Trains compatible

- Body mounted coupler box - accepts Micro-Trains 1015/1016 type couplers

- Motor with 5-pole skew wound armature

- Dual flywheels

- All-wheel drive

- All-wheel electrical pick-up

- Directional LED headlights

- Printing and lettering legible under magnification

- Operates on Code 55 and 80 rail

- Durable packaging safely stores model

- Minimum Radius: 9.75"

- Recommended Radius: 11"

DCC Features -

- ESU-LokSound Next18 Select Micro DCC and sound decoder with Full Throttle or ESU Next18 Micro DCC "motor only" decoder

- Cube-type speaker

- Accurate FDL-16 prime mover and auxiliary sounds, horn, bell, and more

- Operates on both DC and DCC layouts

Grade: A