Introduced: 2018

These gorgeous looking and sweet running TurboTrain sets are available either DCC-Ready or with factory-installed ESU LokSound decoders. Depending on the paint scheme, they come in either three-car or five-car sets. Four-car add-on sets are available for the CN and VIA trains. The various sets are configured thusly -

| United Aircraft | PDC-28 | - | IC-29 TurboCafe | - | PDC-29 |

| Penn Central | PDC-28 | - | IC-29 TurboCafe | - | PDC-29 |

| Early Amtrak | PDC-28 | IC-36 TurboCoach | IC-29 TurboCafe | IC-37 TurboCoach | PDC-29 |

| Late Amtrak | PDC-28 | IC-36 TurboCoach | IC-29 TurboCafe | IC-37 TurboCoach | PDC-29 |

| Canadian National | PDC-27 TurboLuxe Coach | IC-31 TurboBuffeteria | IC-30 TurboCoach | IC-33 TurboClub | PDC-26 TurboClub |

| VIA Rail | PDC-27 TurboLuxe Coach | IC-31 TurboBuffeteria | IC-30 TurboCoach | IC-33 TurboClub | PDC-26 TurboClub |

| Canadian National (add-on set) | IC-31 TurboBuffeteria | IC-30 TurboCoach | IC-35 TurboCoach | IC-33 TurboClub | |

| VIA Rail (add-on set) | IC-31 TurboBuffeteria | IC-30 TurboCoach | IC-35 TurboCoach | IC-33 TurboClub |

(PDC=Power Dome Car, IC=Intermediate Car)

These are great looking models with crisp paint and fine detailing.

PDC

IC TurboCoach

IC TurboCafe

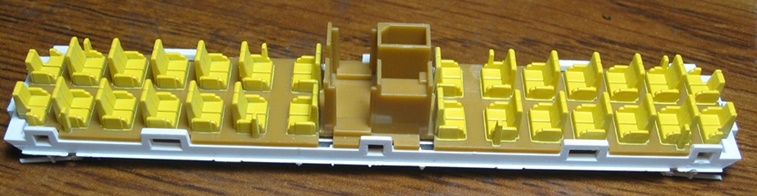

All come with interior lighting and fully detailed interiors -

PDC shells (and all of their assorted detail parts) are plastic -

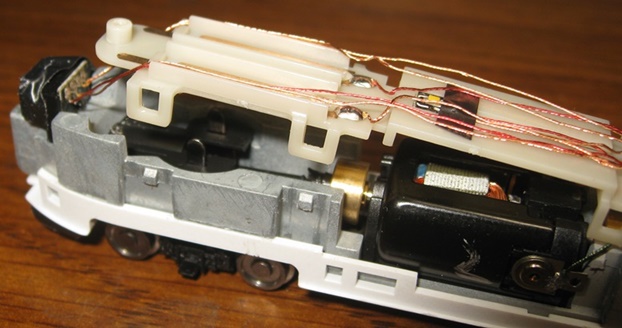

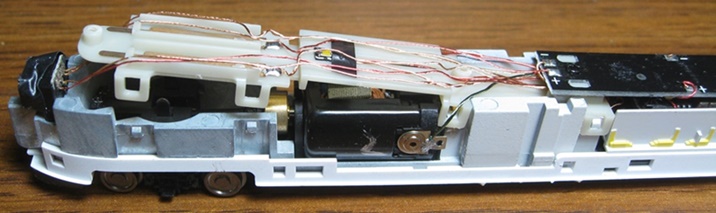

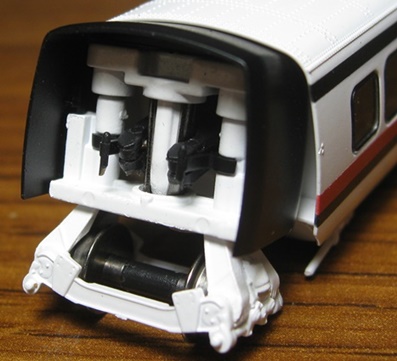

Both of the PDC's included with each set are powered. For the sound-equipped versions, each PDC comes with its own decoder and speaker. The internal mechanism assembly is elegantly simple and compact (and somewhat remindful of Kato designs). The basic chassis is a big hunk of metal, to which the plastic undercarriage detail clips.

The motor is rectangular and open-sided (5-poles / skew-wound). Each motorshaft is equipped with a small brass flywheel. A plastic driveshaft connects the forward flywheel to the truck tower, wherein lives the worm.

Both axles are geared and all gearing is plastic (apart from the worm, which I would assume is brass). Current collection comes by way of thick metal wipers that contact either the backs of the wheels or the axle shoulders (or maybe both, it's hard to tell). For PDC's from the five-car sets, one wheel per axle comes with a traction tire. Plastic shoulders on the truck tower keep the truck seated inside the metal chassis. And although you could probably pull the truck out of the chassis relatively easily, this would involve disconnecting the driveshaft - so, perhaps not something to be undertaken lightly. Wheels are blackened and low-profile (no problems on Atlas Code-55 rails). Speaker holes are provided in the undercarriage. Additionally, all cars are labeled on the undercarriage and have handy-dandy arrows indicating which end is the front.

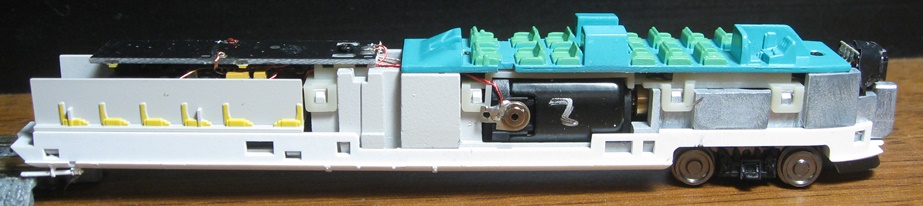

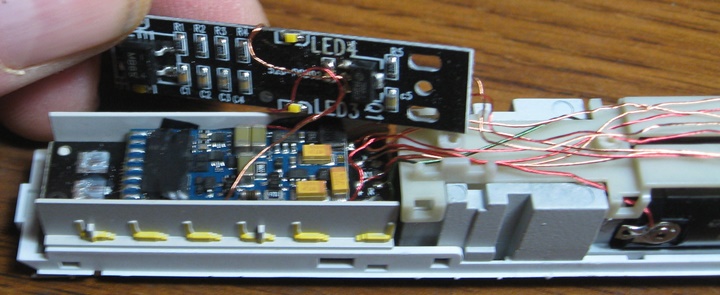

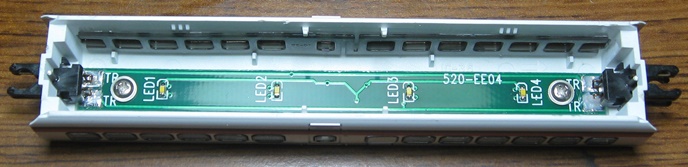

Metal extensions off the wheel wipers brush up against flexible bronze strips attached to a white plastic bracket clipped to the top of the chassis. The contact strips and all of the wiring for track power, motor control and lighting control are hidden away underneath a plastic seating section detail screwed to the top of said white bracket.

An LED board for the directional headlights and gyralights is mounted to the front of the chassis. When moving forward, both headlights are on and the gyralight is white. When moving in reverse, the headlights are off and the gyralight is red. Note that the gyralight is controlled separately from the headlights (with F3 instead of F0).

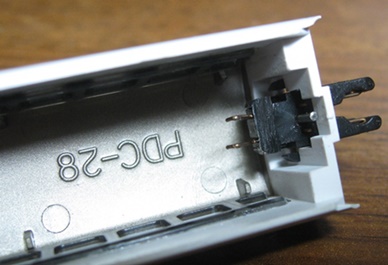

An LED board screwed to the back end of the white bracket provides lighting for the "simulated seating section". The main PC board and decoder board are found underneath the LED board, and the speaker is found underneath all of that. The DCC interface on the main PC board is of the "Next18" ilk. Note that the main PC boards on the two PDC's are not identical. The reason for this is to allow the two to run in the same direction on DCC without first having to reprogram one of the decoders to run "backwards". For non-sound DCC installs, RT recommends an ESU LokPilot Micro (either 54686 or 54689).

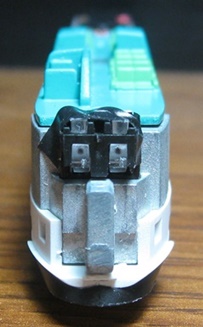

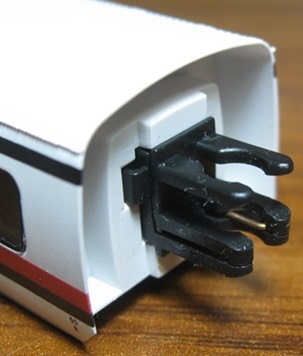

As one might expect, the train is not delivered completely assembled. However, putting things together is pretty simple (and fully explained in the included instruction manual). This involves connecting up a series of single-axle truck / diaphragm assemblies between the cars (with one provided for the rear PDC and each of the IC units). Plastic brackets on the front of each of these cars clip to the center posts on the diaphragm details -

Similarly, the plastic brackets on the back end of each IC (and the front PDC) clip to the other sides of the diaphragms -

Like the PDC's, the bottom of each IC says what it is, where it goes in the train, and which end is which -

The single-axle wheelsets collect current from the rails via dimpled axle-end wipers and share it around via a clever series of electrical contacts embedded inside of the plastic connecting brackets (you didn't really think the PDC's were going to get all of their pickup solely from those two-axle trucks, did you?) In the case of the IC's, current flows through a PC board inside the shell (said PC board also provides the interior lighting). Like the PDC's, the IC shells are all plastic -

The connecting brackets on the PDC's have a couple of stiff metal wires that conduct current to contact pads on the back end of the main PC board in the chassis -

The box includes a full instruction manual / TurboTrain history treatise (which I would recommend reading in its entirety - it's pretty hilarious). Also included are exploded parts diagrams, non-TT wheelsets (if you don't feel like you need the extra pulling power), spare traction tires and spare guidance arms (the white rods between the trucks). I guess the latter are a bit fragile and prone to breaking.

Be it analog or DCC, performance on these models is oustanding in every way. Pickup is flawless (not surprising given how many wheels are conducting current). Throttle response is excellent and the train runs smoothly and quietly at all levels. Slow speed creep is impressive (although I would recommend performing a CV54 "auto tune" to get optimal slow speed performance). The top-end speed is reasonable and realistic. Pulling power is more than adequate, with my five-car train having no problems on curving 2% grades. I didn't have any problems with any of the wheels derailing (even on curves as sharp as 9.75" radius). The sound is robust and nicely rendered. Overall, this may be the most impressive train I've ever run. It's hard to put into words, but it's the first model train I've ever operated that "feels" like a real train and not some tiny N scale toy. I don't know what it is exactly, but it just has this super heavy/powerful vibe to it. So, definitely an instant classic, and one that has quickly become one of my personal favorites. Kudos to Rapido Trains for hitting another one out of the park!

Prototype -

The United Aircraft TurboTrain is an important part of Canadian railroad heritage. The Turbo was a high-speed passenger train that operated in Canada and the United States from the 1960s to the 1980s. To this day, it is the fastest production train in North American history. It achieved the American speed record of 170.8 MPH in 1967 and the Canadian speed record of 140.6 MPH in 1976, both of which still stand today.

The TurboTrain was designed and marketed by United Aircraft Corporate Systems Center (later Sikorsky Aircraft) as a gas turbine-powered, high-speed intercity train. Each train was powered by four or five Pratt & Whitney ST-6 gas turbine engines, with an additional gas turbine providing auxiliary power. The Turbo featured a unique pendular suspension over articulated single-axle trucks, which allowed the train to tilt in curves. That feature, combined with the short Intermediate Car length, meant that the Turbo could travel much faster than regular trains on conventional track. It was a high-speed train without the need to invest in high-speed train infrastructure.

The American TurboTrain operated first for Penn Central and then toured the United States in 1971 to introduce the nation to Amtrak. The Amtrak Turbo operated mainly between New York and Boston until 1976. In Canada, the Turbo operated first for CN and later for VIA Rail Canada. Operating between Montreal and Toronto (and, for a time, Ottawa), the Turbo became one of the most reliable trains in the country. Sadly, the Turbo era came to an end in 1982. Each and every Turbo was scrapped.

- Accurate dimensions scaled from original blueprints

- Two powered Power Dome Cars with smooth, reliable drive systems

- Articulated single-axle trucks with needlepoint axles

- Full interior detail with interior lighting

- Different Canadian and American versions with accurate details

- All wheels pick up power for electrical reliability

- Working headlights, tail lights, and Gyralites

- Prototypically-tinted windows

- CN and VIA customers can add a four-pack of Intermediate Cars to complete their trains

- Sound-equipped models feature a sound decoder and sugar cube speaker in each Power Dome Car

- Sounds are accurate Turbo sounds sourced from original Betamax video recordings

- Sound decoders are custom ESU LokSound with amazing sound quality

Shell Removal -

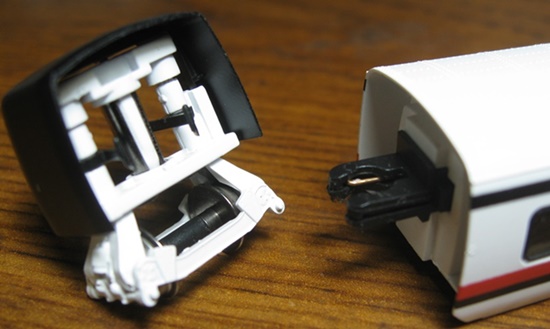

To remove the shell from a PDC, the first step is to pull the nose off (simple friction holds it in place). The shell is held to the chassis by four claw-like tabs on the inside of the shell. To free these up, grab hold of the shell with both hands, insert your thumbnails between the shell and chassis on either side and spread the sides of the shell apart. Starting from the front and moving towards the back seems to work best. Once the tabs are freed up the shell should pop right off.

The same basic procedure applies to the IC's, although I found these to be much more difficult. I basically had to resort to a lot of poking and prying with small screwdrivers to separate the sides of the shell from the chassis and get the tabs loose. And forget about using fingernails, it's hopeless. In fact, unless you're keen on damaging your IC's shell, I'd suggest just leaving things well enough alone.

Grade: A