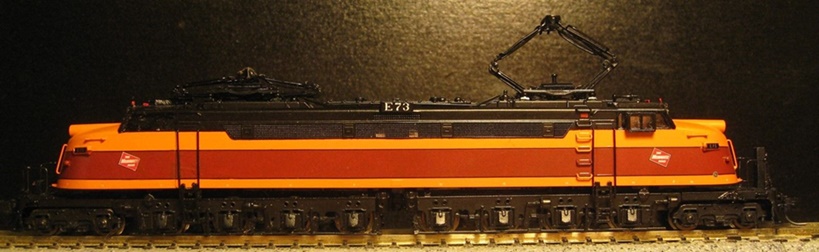

Introduced: 2007

This model was released in a variety of configurations: E20, E21, E73, E74, E75, E76 and E79 (with something like 20 of each having been made). And although very pretty looking models, it's my sad duty to report that they are not good runners (but more on that in a moment).

Internally, these are quite a departure for Ajin -

The chassis is a simple brass strip (with the shell providing most of the model's heft). And for reasons only Ajin can explain, they decided to go with two motors (open-sided / skew-wound / three-pole). Each motor has a single flywheel-equipped driveshaft that connects to the worm by way of plastic U-joints. All eight axles on the inner two trucks are geared (with all of the gearing being metal).

All sixteen wheels on the inner trucks provide pickup by way of wired wheelback wipers. The truck wiring connects to PC boards mounted on top of the motors. Said PC boards contact each other, thus sharing current. Sticky-uppy contacts on one of the boards transfers current to the directional lighting electronics mounted inside the shell. One of PC boards uses wires to transfer current to its motor, whereas the other uses phospher bronze "U" clips. The outer two trucks provide neither pickup nor propulsion. The pantagraphs are sprung and moveable (although they are non-functional - IE they don't conduct current). Micro-Trains couplers come mounted to the outer trucks. The minimum radius for curves is right around 15" (any sharper than that and the outboard trucks start derailing).

As strange as the decision was to go with two independent motors (a presciption for trouble if the two aren't perfectly speed-matched), these models actually have a couple of other design flaws that are even more dire than that. Making matters worse, a good number of these models have some rather tragic assembly errors. To wit -

- Cutouts in the frame provide room for the flywheels to spin. However, if the flywheels aren't positioned "just so" on their driveshafts (IE, directly over said cutouts), the flywheels will actually contact the frame (grinding metal off both the frame and the flywheel, and creating a lot of excess friction and noise in the process).

- The motors are mounted very loosely to the frame - basically being free to move around wherever they like. Also, the round cutouts in the motor mounts (wherein the driveshaft bearings seat) are too large relative to the bearings (thus introducing more slop into the equation). And the net result is, once again, a whole lot of noise.

- Due to poorly designed mounts, the truck sideframes tend to ride too low (allowing some of the detailing to actually scrape the rails as the locomotive rolls along).

Out of the box, my Joe ran well enough (at least as far as pickup and throttle response were concerned). Pulling power is exceptional, with mine able to haul twenty assorted heavyweight passenger cars like they weren't even there. Unfortunately, due to all of the above-mentioned design/assembly flaws, it also ran loud enough to wake the dead (not to mention hot enough to melt butter). Fortunately, I have ready access to Ron Bearden (noted N scale locomotive guru) and he was able to suss out (and fix) all of its various woes in fairly short order (detailed HERE). So, if you're a skilled tinkerer (or have access to Ron), these can be outstanding runners (smooth, quiet, etc). But if not? Well, get out the earplugs my friend...

To remove the shell, simply unscrew the six small screws on the underside of the chassis (two on each end and two in the middle). The shell should lift off relatively easily at that point, although the PC boards can be a bit of a sticking point. If that turns out to be the case, just bend the sides of the shell slightly outwards to clear the obstacles.

Grade: D (as delivered, although a solid "A" when properly tuned)