| RDC-1 | RDC-2 |

|  |

| RDC-3 | RDC-4 |

|  |

| RDC-1 | RDC-2 |

|  |

| RDC-3 | RDC-4 |

|  |

Introduced: 2001 and 2009 (Kobo Jet Powered RDC)

These models are generally available in two-car sets (although Kato has, in more recent runs, made single cars available as well). The RDC-1, RDC-2 and RDC-3 all share the same basic chassis / mechanism. The RDC-4 chassis is different (it being a bit shorter than the other three). All of them come with a few ala-carte exterior detail parts (to be installed by the modeler).

Each unit is powered by an open-sided, straight-wound, 5-pole motor. The chasses are plastic (for the most part), making these models quite light. All wheels are geared and provide pickup (no traction tires). All gearing is plastic. LED-equipped PC boards on either end of the chassis provide bi-directional lighting (that changes color based on direction of travel). Unfortunately, there is no interior lighting (although Kato does sell add-on interior lighting kits for these models - the same ones used in their passenger cars). These models come with shell-mounted semi-operational knuckle couplers. Also included are a pair of Kato's automatic/magnetic couplers (should you want to switch). Wheels are blackened and low-profile (no problems on Code-55 rails).

Performance is outstanding - throttle response is smooth at all levels, pickup is flawless, and slow-speed creep is excellent. They have no problems on extremely sharp (9.75" radius) curves. On the downside, these models do lack flywheels. Consequently, they tend to start and stop rather abruptly. And as mentioned above, they're quite light, so they're not particularly strong pullers (not that one would necessarily be pulling long trains with one anyway). Lastly, the top-end speed is excessively high (not a huge concern for me, but what the hey).

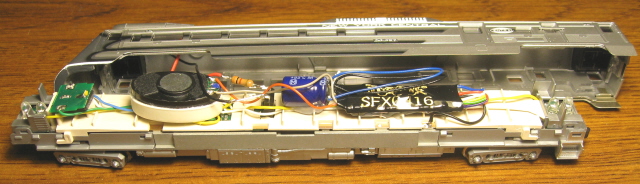

And from the "You've Got To Be Kidding Me" department, Kato also released a special limited-edition "jet powered" RDC-3 with DCC sound and lighting in the fall of 2009 -

This model was released through Kato's "KOBO Custom" division (said division specializing in DCC-equipped releases). And although crazy expensive ($300), it's one heck of a lot of fun.

Features -

- DCC motor control

- DCC Sound with variable engine levels for both engine and booster, and horn functions

- DCC controllable head, tail and interior lights, with separate controllable flickering booster ignition light

- Custom built streamlined nose cowling with air-speed sensor

- Custom Painted bodyshell with streamlined lower skirts

Prototype information (standard RDC) -

Commonly known as the "RDC," the motorized Rail Diesel Car generally operated in rural areas where ridership and mail/parcel transport were too low for regular passenger train service. When first introduced, the RDC was proclaimed to be the savior of branch line and suburban service. It was heavily used as a commuter service workhorse (and still is currently in some locations!). Capable of being operated by a motorman from either end of the car, these units could be used independently or combined into a multi-unit.

Prototype information (jet powered RDC-3) -

The 1966-built New York Central "Black Beetle" Jet-Powered RDC was a one-of-a-kind piece of railroad equipment. Equipped with a pair of boosters from a Boeing B-47 "Stratojet" bomber, the modified RDC-3 broke land speed light rail records with speeds of over 183 miles per hour.

Kato's RDC's are fully DCC-Ready. However decoder installation is a bit of a bitch (at least until you've done it once). I've had decoder installs in old pre-DCC locomotives that took less time (this took me about 4 hours the first time). No, you don't need to fire up the old soldering iron, but the Rubik's Cube-like assortment of delicate and intricately connected chassis parts makes for one hell of a challenging install. Here's some tips that might help:

To remove the shell, insert a couple of toothpicks or skinny screwdrivers on either side near one end and push out to free the shell clips from the frame. Be sure to get the tool between the chassis and the window insert. The shell should just lift off at this point.

Use a small screwdriver to pry up the little white plastic clip from the middle of the seat section. Carefully bend the now revealed motor contacts up so they're no longer bent over the brass strips on the seat section. Remove the little plastic clips that hold the LED boards in place on either end of the chassis (set aside the lightboards, you won't be needing them anymore).

Use a small screwdriver to pry off the four "L" shaped clips that hold the ends of the seat section to the chassis (two on each end).

Now the tricky part. There are two plastic clips on the bottom of the seat section holding it to the chassis. Take your best guess as to where they are (by lifting up on the seat section and seeing where it's being held to the chassis) and then slide a small, flat screwdriver under the seat section. Push inwards to free the clip from the chassis and then apply upwards pressure to free the seat section from the chassis (repeat for each side of the two clips). Take your time, it's easy to break the clips if you're not careful. Once the seat section is free, lift it and the four brass strips for the lightboards off the chassis.

Addendum - I'm informed that it's much easier to get at these clips from the underside of the chassis - just remove the fuel tank and they should be clearly visible (or so I've been told).

Remove the large white piece of plastic "filler" from the chassis and set it aside, you won't be needing it anymore.

The decoder mounts to the underside of the seat section, with the lightboards going on the top side. So, push the lightboards and wiring through the large hole in the seat section and then mount the decoder to the underside of the seat section (it doesn't really clip in place, but don't worry about that). Next, rebend the motor contacts so they aren't pointing straight up anymore. Make sure they're still high enough that they're going to touch the contacts on the decoder board, and make sure that the brushcaps haven't rotated and caused the motor contacts to point at funny angles or possibly even touch the frame.

Reattach the seat section to the chassis (starting with the large center clips). Make sure as you push down that the motor tabs are lining up with the contacts on the decoder board. Once the center clips are clipped, do the "L" shaped clips on the corners. Lastly, reattach the white plastic clip on top of the seat section. I like to run the wires for the forward lightboard under the clip, as it helps to hold them down and make them less visible through the windows. At this point, I also like to verify that the decoder is working correctly, and that the motor is operational. So, stick it on the rails and see what happens.

Now it's time to reinsert the lightboard brass strips - another tricky procedure. Slide them in, making sure that they are under the seat section and on top of the seat section brass strips (sandwiched between the two). The long end goes in. On the other end, the little bend at the end of the strip should be pointing down. Use a small screwdriver to push each strip in until it clips into place (there's a little nub on the chassis that goes into a hole on the strip).

Insert the end lightboards inside the little gray plastic clips and clip them back to the chassis. Digitrax's instructions suggest using a knife to carve channels for the wires to run between the chassis and the bottom of the clip, but I never found that necessary. At this point I like to verify that all of the lights are working correctly, so stick it on the rails and see what happens. If one of the end lightboards isn't working, try bending the brass clips underneath said lightboard up to get better contact with the contacts on the bottom of the board.

Lastly, it's time to "mount" the interior lighting board (another fun bit). Digitrax provides a so-called clip that, unfortunately, doesn't actually clip to the seat section. Worse still, the lightboard its supposedly designed to hold doesn't clip in either. So, stick the board in the clip as best you can and then stick the clip in the slot provided in the seat section and hope for the best. Now, put the shell back on and go have some fun. You've earned it!

Grade: A

Reviewed: 05/02 Model Railroader ("After admiring the crisp detail on Kato's new N scale Rail Diesel Cars (RDC's), my next immediate thought was, "So, where the heck's the motor?" That's because I could look right through the side windows of these well-engineered DCC-ready models. Taking a design cue from the prototype, Kato has cleverly concealed the motor and drive train within the floor, which preserves the see-through effect... Kato's models represent the early versions of Budd's RDC-1, RDC-2 and RDC-3, produced from 1950 to 1956, as well as a correctly proportioned early-version RDC-4...

"Kato has mounted a five-pole, straight-wound, open-frame, double-ended motor horizontally inside the cast plastic frame that extends the length of the model. Two long acetal plastic drive shafts connect the universals on the motor shaft and the trucks. Brass worms transfer the motion to all four axles. The wheels are chemically darkened and match NMRA standards. Power is conducted through the wheels to brass bearing plates holding the axle ends. A series of phosphor bronze pickups and internal contact strips transfer the current to the motor. Digitrax recently has introduced its DN122 decoder, which is designed to fit all four Kato RDC models. Installation involves partially disassembling the model, but no soldering is needed. The models have directional amber LED headlights and red LED rear marker lights... Kato also offers an interior lighting kit as a separate item. The short-shank couplers are body-mounted... providing close coupling on curves of 9.75" or larger. Kato also includes long shank couplers for use with tighter curves. Both styles of couplers are designed for manual operation, so if you want automatic magnetic uncoupling, you'll also need to install the metal trip pins Kato provides... The couplers on our models were mounted too low...

"The details and dimensions on all four of Kato's models closely matched prototype drawings... The paint on the crisply molded models is evenly applied and the lettering is excellent. The window edges are outlined in black, simulating rubber seals, and the cast-on, painted windshield wipers are well done. The purchaser needs to attach the gray cast-plastic horns, roof-mounted air vents, and the mail hooks which press-fit into holes cast into the RDC-3 and RDC-4. The black plastic trucks have good relief detail. The radiator assembly is a separate piece that comes installed. Our models started smoothly and were quiet except at the higher speed ranges. The absence of a flywheel undoubtedly contributes to their proclivity to "get up and go", a common prototype characteristic. However, our models far surpassed realistic, operating speeds... The drawbar pull on the RDC-1, -2 and -3 is equivalent to about 15 cars... The lighter RDC-4's drawbar pull equals about seven cars... And although they'll operate on 9.75" curves, RDCs are long pieces of equipment and will look much better on broader curves. Apart from the coupler height, Kato's RDCs are superb models. Alaska, Budd, CN, CP, C&NW, JC, NH, NYC, NP, RI, SF, WP, Undec $79.98 single car, $159.98 two-car set")