Introduced: 1988 (Non-DCC F3), 1992 (Non-DCC F7), 1995 (Revised F3), 1996 (Revised F7), 1999 (Re-Revised F7), 2003 (DCC-Ready F3), 2006 (DCC-Ready F7), 2013 ("Late" F3), 2014 (F2), 2016 (KOBO DCC F7), 2017 (DCC-Equipped F7B) and 2023 (DCC-Sound F7A/B)

All of these models have followed the same evolutionary path and share the same internals, so I'm going to save myself a bit of time and cover them all here. Having said that, there have been two distinctly different versions of the basic F unit chassis (and with the later version having a number of major improvements over the original).

The first-run chassis is all-metal, split-frame and very heavy. The motor is an open-sided 5-poler with dual flywheels. All wheels are geared and provide pickup. All gearing is plastic. Prior to the 1999 production run, couplers were Rapidos. Starting with the 1999 F7 release, they were upgraded to Kato's proprietary "semi-operational" knuckle couplers. On "A" units, the pilot coupler is clipped to the shell, whereas the rear coupler is truck-mounted. Both couplers on "B" units are truck-mounted. "A" units have a directional headlight mounted to the chassis. The wheel flanges on the first run of F3's (1988) are slightly oversized, resulting in a bit of rumbling on Atlas Code-55 track. The flanges were downsized slightly in subsequent production runs, so no more C55 issues.

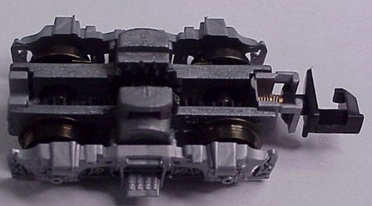

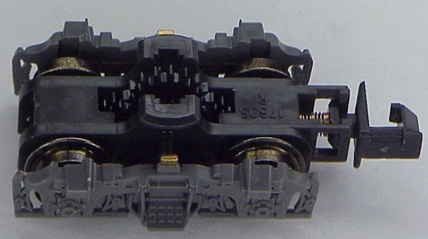

There were two different styles of truck used on these early models. Originally they came with metal / split-frame trucks similar to the ones used on the Atlas/Kato RS-3. Current flows from the metal truck halves directly into the chassis (a somewhat problematic scheme that required a fair amount of attention in order to keep things running properly) -

Starting with the 1995 F3 release, the trucks were changed to plastic assemblies that used low-friction phospher-bronze "axle-cup" style pickup contacts. Sticky-uppy wipers on the contacts transfer current to metal strips on the chassis. These trucks were a great improvement over the original design; simultaneously improving chassis current transfer while decreasing drag -

Performance on these early units is most impressive. Excellent throttle response, smooth acceleration and deceleration, superb slow-speed creep, and pulling power to spare. Pick-up is flawless and no problems on narrow radius curves. These do run just a little louder than we're used to seeing from Kato, but not so loud as to be annoying. The top-end speed is a little higher than it needs to be, but that's a minor quibble.

My main complaint with this first version is the Micro-Trains coupler conversion. Although the actual installation of said couplers is pretty easy, I've never been real happy with the end results (as is usually the case with these "coupler saddle" type installations). The couplers are not firmly seated (resulting in a lot of up-and-down yawing) and consequently, unplanned uncouplings are pretty common.

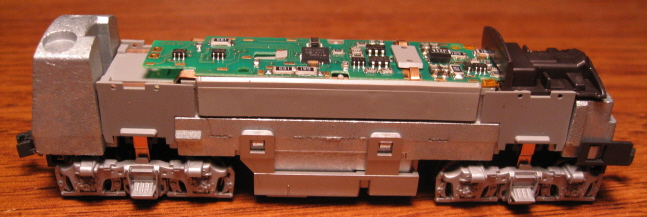

In 2003, the F3 models were re-released with a slightly redesigned shell and a completely redesigned mechanism (and with the F7 models getting the same treatment in 2006) -

The old semi-operational couplers were replaced by Kato's automatic/magnetic knuckle couplers. The shells were modified to include illuminated number boards. And most noteably, the trucks and chassis were completely redesigned (now with full support for DCC). Here's mine (with decoder installed) -

This new design is a definite improvement over the original - super smooth, super quiet and just plain perfect. And with the addition of the new automatic couplers, definitely meriting an unequivocal "A" rating. My only (minor) quibble is with the somewhat convoluted decoder installation procedure. Definitely a bit more challenging than the typical "drop-in" Kato installation, involving partially disassembling the mechanism and slathering Digitrax's magic yellow tape all over the place (similar to the old Kato E8 and PA procedure, if memory serves me).

This new mechanism employs a Kato design feature that would eventually come to be known as "shock absorber construction". Unlike previous models (E8, PA, etc), where the metal contact strips on top of the chassis were free to move up and down, the contact strips on these models are firmly fixed in place (tucked into the chassis on the ends and firmly pinned down by the lightboard in the middle). Whether by design or by accident, this resulted in a much quieter ride (and would subsequently be emulated in many of Kato's future models).

There's a lot less metal here, so the newer chassis is noticeably lighter than the original version. This may impact pulling power, but since I generally run these in A-B or A-B-A consists, I've never hit the wall as far as their ability to pull long trains. Overall, these are completely outstanding models in every way.

Shells can be swapped between the two versions, however some modification to the plastic window inserts may be necessary in order to get a good fit (or so I've been told). Keeping the window inserts with their respective chasses reportedly helps to simplify the procedure.

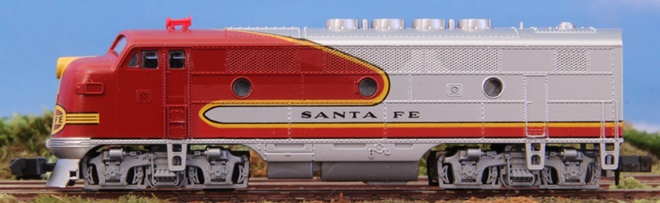

F7 models are available in both single and dual headlight configurations (depending on the prototype).

F3 models are available in three different configurations: Phase I (three portholes per side, small numberboards) Phase II (two portholes per side, large numberboards), and "Late". The late version (released in 2013) has F7-style stainless steel grills (as opposed to the old "chicken wire" grills used on the early versions). Steam generator details are also optional (depending on the prototype).

Phase I

Late

Kato released F2A and F2B models in 2014 (being basically the same as their Phase I F3's). Model features include dual headlights as well as optional dynamic brake and steam generator details (as per the prototype) -

Kato released a couple of different DCC-equipped F7A and F7B sets under their Kobo Customs banner in 2016. Decoders were from TCS. DCC-Sound versions with ESU LokSound decoders were released in 2023.

Kato released a slightly revised version of their F7B in 2017 (as part of their Milwaukee Road Olympian Hiawatha passenger train release), with the main difference being the addition of a winterization hatch. This model was also the first non-custom Kato F unit to be available with a factory-installed DCC decoder -

To remove the shells, stick some toothpicks (or small screwdrivers or whatever) between the chassis and the window inserts (by each truck) and spread the sides of the shell outward a smidge. The shell should lift up and off at that point. For "A" units, you'll first have to remove the pilot coupler (and good luck putting it back - it's loads of fun). Be careful with the ladder extensions on the shell - they're quite fragile and snap off with little or no provocation.

Grade: A (although "B" on the first version for MT coupler users)

Non-DCC F3 Reviewed: 2/89 Model Railroader ("Like most diesels, the F3 changed over the years as newer and better equipment was developed. Aware of these "revisions", Kato offers the F3 in two production versions. The Phase IA unit has three portholes in the sides, while the Phase II has only two. Original roof fans had a high, squared shroud around them, as did the early Phase II models. However, some of the last F3s built had low fans and looked like the later F7s. Our sample units were painted and lettered for the Union Pacific. Careful scrutiny showed some letters were a little ragged and some very small areas filled in. The red lettering didn't have the fine UP black outlining, but that's a little much to expect in N scale. The injection-molded plastic bodies are highly detailed, including the simulated chicken wire screening that covered the side vents. On the A unit this extended down between the two portholes, while on the B it covered only the vents. Because the Phase I and Phase II units were dimensionally the same except for slight exterior changes, Kato's models of both the A and B units closely follow the scale dimensions of the F3 Phase I plans found in MR.

"The zinc-alloy mechanism frame is cast in halves that must be insulated from one another with plastic bushings because they are part of the electrical pickup system. The frame assemblies of the A and B units are identical, except for the clear-plastic window inserts on the sides. These window castings interlock into the sides of the mechanism, and the inserts slip into the portholes to hold the body and frame together... Kato uses an open-frame, five-pole motor with brass flywheels at each end to drive the model. The worms are brass, and the worm gear and drive-train gears are tough slippery plastic. All eight wheels on each unit are used for electrical pickup. Our samples ran smoothly at all speeds, with changes cushioned by the flywheel effect. At mid-voltage the models have a scale speed about equal to the real locomotive's 65-mph maximum rating. Recorded values such as amperage, speeds, and drawbar pull doubled when A and B units operated together. These models performed nicely on tight curves, easily negotiating ones with a minimum radius of 9 inches...

"The plastic sideframes on the trucks follow the standard EMD Blomberg design. All the metal wheelsets were found to be slightly narrow when checked with our NMRA standards gauge... Each unit has sufficient drawbar pull to handle approximately 24 free-rolling freight cars on level track. This gives the model about the same capacity as the prototype. Our samples had nearly identical operating speeds, which is essential for getting the most pulling efficiency out of multiunit sets. In short, Kato's F3 A and B units are attractive, fine-running models. About all we did to our UP models was paint the cast-metal frame black behind the clear portholes. Otherwise, they were ready to roll.")

Non-DCC F7 Reviewed: 7/92 Model Railroader ("These new N scale diesels from Kato are models of some of the best-known locomotives that were ever built... These F7s are excellent replicas, nicely proportioned and well detailed. Their dimensions match the F-unit drawing published in MR... Their details and horizontal louvers are typical of those units which were built by EMD prior to November of 1951. Kato's F7s follow the same proven design and construction methods that were used in the firm's EMD F3 diesels... Each F7 model has an injection-molded styrene plastic body, clear styrene glazing, and a power chassis made of zinc alloy, engineering plastic, and brass. Just about every bit of space inside the model has been filled with weight. The mechanism has a five-pole motor, brass flywheels, blackened brass wheelsets, and directional lighting.

"Our sample performed well without any additional lubrication. It started moving and ran steadily and quietly at only 2 volts. At half throttle, the speed is just about right for mainline freight service. Eight volts puts it into in the passenger speed range around 90 to 100 mph. Full throttle creates both excessive speed and noise, so most modelers won't want to run it that fast. The F7's speeds are similar to the Kato F3's, so they be intermixed realistically. The F7's drawbar pull is equivalent to about 24 free-rolling freight cars on straight and level track. Three units in an A-B-A combination had a drawbar pull equivalent to about 68 cars. Our sample F7s came neatly painted in a CN color scheme introduced in the early 1970s. The other models have plastic bodies matched to the paint schemes they carry. Dual headlights appear on the ATSF, BN, SP and UP A units, while single headlights are found on the CN and PRR A units. The ATSF passenger B unit has steam generator details on the roof. Rapido-type couplers come mounted on all the F7s... These Kato F7s are excellent models that will enhance any N scaler's enjoyment of first-generation diesel railroading. ATSF, BN, CN, PRR, SP, UP, Undec. $69.98")