AC-8

AC-10

AC-11

AC-12

AC-8

AC-10

AC-11

AC-12

Introduced: 2010 (DCC-Ready version) and 2012 (DCC-Sound version)

This was Intermountain's first N scale steam locomotive, and it made for quite an impressive debut. Overall performance is outstanding and the shell detailing is beyound exquisite. The line includes AC-8's, AC-10's, AC-11's and AC-12's. However, model-wise I'm told that the AC-8 is the only one that differs physically from the rest (having different features around the headlight and radiator grills). Apart from the paint and road numbers, the AC-10's, 11's and 12's are all identical.

The motor is a skew-wound 5-poler with dual flywheels. Pickup is provided by 12 of the 16 drivers (the forward driver pair on each engine being equipped with traction tires). Wired wheelback wipers are used to collect current on one side (with current flowing from the axles to the engines and ultimately through the chassis on the other). The tender trucks also provide pickup, with the forward truck picking up left rail current and the rear truck picking up right rail current. Only one axle per engine is geared (with the rest of the drivers being turned solely by the cranks). Unfortunately, the geared drivers on the rear engine are not the ones with the traction tires (go figure). Apart from the brass worms, all gearing is plastic. Lighting is provided by LEDs mounted inside the cab and the tender (yellow on the first run, white on subsequent runs). The tender "back up" light is directional, whereas the headlight and numberboard lighting is not. Micro-Trains couplers are mounted inside the pilot and on the bottom of the tender chassis.

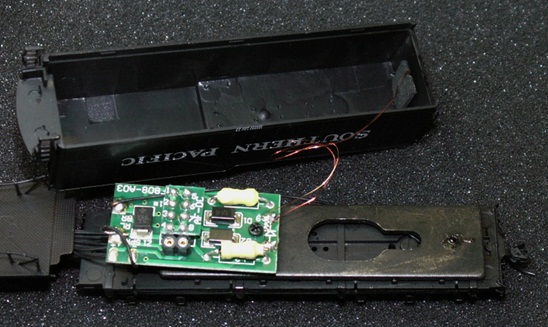

The model is available either DCC-Ready or (as of 2012) with a Soundtraxx Micro-Tsunami sound decoder and speaker. Both versions are equipped with a standard 8-pin NMRA-style DCC socket on the tender PC board and speaker holes in the tender floor. A 7-wire harness plugs into the tender PC board and runs forward to the PC board in the locomotive.

The sound on the DCC-Equipped models is OK, but then again it's not really wowing me either. The speaker isn't mounted to anything and the speaker enclosure itself is pretty minimalistic (as compared to, say, the speakers in Athearn's Big Boys and Challengers). Consequently, the sound is a bit thin and tinny (at least to my ear). Also, I find the endless whine of the "turbo-generator" to be a bit grating. It may be accurate (vis'a'vis the prototype), but as reproduced in this model it all sounds like so much transistor radio static to me.

Wheels are relatively low-profile. However, the pilot truck, trailing truck and tender wheels hit the spike heads on Atlas Code-55 track (resulting in a bit of rumbling). Replacing them with Fox Valley .540" axle wheelsets is one way to deal with this issue (36" diameter on the tender, 33" diameter on the trailing truck, and 28" diameter on the pilot truck).

Performance is virtually flawless. It runs smoothly and quietly at all throttle levels. No binding or wobbling. Throttle response is nimble and slow speed creep is excellent. Pulling power is off the charts (50+ cars on level track). I didn't have any problems with the wheels derailing on curves as sharp as 11"-radius, although that's probably pushing it. I'd say that 15"-radius is a more realistic minimum as I've read plenty of reports from others who weren't so lucky with their 11" curves.

On the downside, some folks have registered consternation over the model's somewhat pokey top-end speed (44 mph by my measurements). This is quite a bit lower than the prototype's reported top speed (75 mph according to Wikipedia). Although one does wonder if the SP ever really ran them that fast in normal freight service. Still, it does seem to be a point of contention with those who like fast-running steamers.

The only minor issue I ran into (apart from the Code-55 wheel rumbling) is with the pilot. It is mounted extremely low - almost skimming the tops of the rails. And when faced with curving track, it will actually make contact with the rails if it encounters any sort of unevenness in the track (a small dip, whatever). Not the end of the world, but it does often result in an annoying squeak. I solved the problem by sanding a bit off the bottom of the pilot.

As noted above, the level of detailing on these models is astounding. Right down to the fully detailed cab interior -

And as wonderful as all of that detailing might be (beyond that of even brass), it does require that one handle these things like they were fine china. Much of the detailing is simply press-fit (rather than glued on). And any sort of careless manhandling is going to cause tiny little bits and pieces to start raining off in droves (and have fun figuring out where they all came from).

So, a couple of minor caveats. But overall, these are amazing looking locos that run every bit as good as they look.

Here's what Intermountain has to say about them -

"This is the first release of the Southern Pacific AC-12 Steam Locomotive in N scale. The detail features are eye-catching, including cab interior. All drivers are powered, and side/main rods operate. The smooth drive includes traction tires for pulling power. The model is equipped with Micro-Trains couplers."

(Note that despite Intermountain's assertions to the contrary, Nakamura and Samhongsa both made brass AC-12's that predate this one; in 1984 and 1990, respectively).

Removing the boiler shell is a fairly daunting task. And frankly, given the hundreds of press-fit detail parts, I suspect I'd completely destroy mine were I to even try. However, I'm told that the way to do it is to first remove the screw hidden underneath the steam turret (the steam turret is the little square box press-fit to the top of shell immediately behind the cab). Next, remove the screw hidden underneath the feed water heater (the feed water heater is the rectangular box press-fit to the top of the shell immediately behind the smokestacks). Once the two screws are out, the boiler shell is almost ready to pull off. But first you need to find the railings/piping that run along the edge of the boiler and into the back face of the cab. Slide these railings back towards the smoke box/stack so they clear the cab. Once they are out of the way you should be able to remove the top of the boiler.

The cab roof is held on with clips and should pop off with a little bit of careful prying.

Grade: A (with the above caveats)