Introduced: 2023

BLI's gorgeous-looking and smooth-running Mallets all come equipped with factory-installed Paragon4 DCC Sound decoders. They run equally well on analog and DCC layouts (although analog users will need one of BLI's "DC Master" control boxes in order to take advantage of all the sound features). Support is provided for BLI's "Rolling Thunder" external sound system. These are sold in two different variants - Type A ("Standard Bell Ringer") and Type B ("Prime Bell Ringer") -

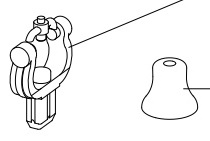

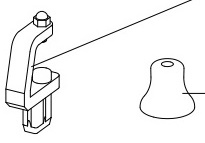

| Standard | Prime |

|  |

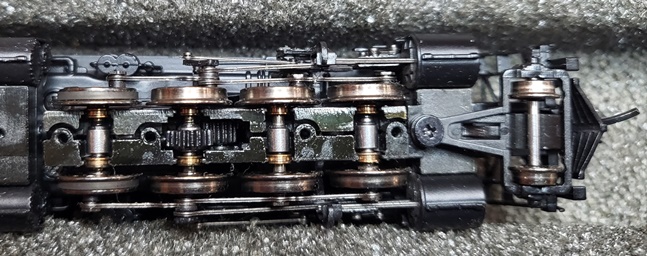

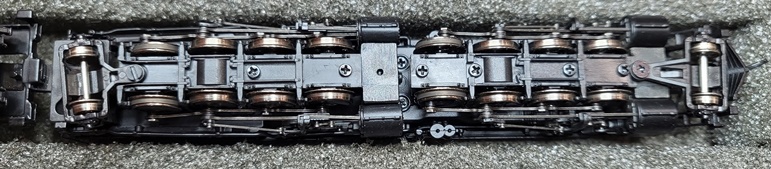

The locomotive shell is metal and divided into two halves (with the lower half serving as an ersatz chassis for the moving parts). The motor is a closed-sided can, which probably means that it's coreless. Each motorshaft is equipped with a small flywheel. Plastic "notched cup" u-joints on the ends of the motorshafts spin "spiked donut" connectors on the wormshafts. The brass worms live inside of lidded plastic boxes on top of the engines. The forward engine is held to the chassis by a sprung screw. The rear engine appears to be held inside the chassis by the top of the worm box.

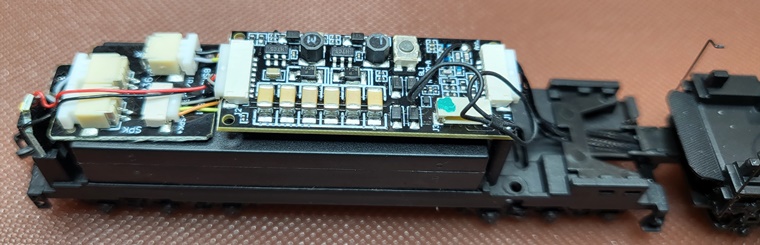

The engines are split-frame, with each having a pair of wires that transfer current to a PC board screwed to the top of the chassis. Two wires from the PC board transfer current to the motor and an additional two wires transfer current to the headlight. The headlight is white and very bright. Six wires (for track power, motor control and lighting control) run from the PC board, through the drawbar, and ultimately to the decoder in the tender. Said wires are fixed inside of a plug that connects to a socket on the decoder board. So, to completely separate the tender and the locomotive you would need to remove the tender shell and pull out the wiring plug.

All sixteen drivers provide pickup, although the rearmost pair of drivers on each engine is equipped with traction tires and so are probably only marginally effective at collecting current (if they do at all). Current flows from the drivers, to the axles, and then ultimately to the engines by way of round brass bushings that seat inside cutouts in the engine halves. The pilot and trailing trucks are electrically neutral. One axle per engine is geared, with the rest of the driversets being turned solely by the running gear. Apart from the brass worm, all gearing is plastic. There doesn't appear to be any lubrication on the gears (or if there is, it's very light).

The pilot is equipped with an operating coupler (I'm not sure what brand, but it looks something like an Accumate). A plastic stud holds the front of the drawbar to the locomotive chassis. The rear of the drawbar is basically held in place by the wires (aided by a small protrusion off the bottom of the drawbar that keeps it from pulling out too far). The wheels are blackened and low-profile (IE no problems on Atlas Code-55 rails). A small baggie in the box contains a number of spare traction tires. It also includes the second bell option (different from the one installed on the model).

The tender chassis is metal (as is the shell). The coupler is chassis-mounted (and once again, sort of like an Accumate). All-wheel tender truck pickup comes courtesy of pointy-ended axles and dimpled axle-cup wipers.

Wires soldered to the axle wipers transfer current to a PC board screwed to the top of the chassis (which is in turn wired to the decoder). All of the PC board wiring has plug/socket connectors, which is kind of nice. An additional pair of wires transfer current to the backup light LED board on the back of the chassis.

Note that the behavior of the headlight is a little strange (as least as compared to what we're normally used to). When the locomotive is first put on the rails there is no sound and no headlight (regardless of whether F0 is selected or not). The sound comes on once the locomotive starts moving (and stays on until either you mute it with F8 or recycle track power). As for the headlight, that doesn't come on until about three seconds after the locomotive has started moving (and then, like the sound, stays on until you either deselect F0 or recycle track power). The headlight is directional insofar as it will get brighter when moving forward and turn off when moving backward.

Be it in analog or DCC mode, these are impressive runners in all respects. Right out of the box, mine performed flawlessly (no preemptive wheel cleaning or lengthy break-in period required). It ran smoothly and whisper quiet at all normal operating speeds. Slow speed creep (at speed step 1) is one-tie-at-a-time and the top-end speed is reasonable and realistic. Pulling power is off the charts (50+ cars through curves on level track). Pickup is superb, with mine able to creep through non-powered frog turnouts without so much as a stutter. I didn't have any problems with any of the wheels derailing (even on 9.75"-radius curves). The sound feature is impressive, although most folks may find the default volume settings a bit excessive (as delivered, the thing is obnoxiously loud to my ear). The couplers function quite well (they readily auto-couple and don't spontaneously come uncoupled). Overall, these are outstanding looking models that run every bit as good as good as they look.

Prototype -

The Y6b was known as the workhorse of the Norfolk & Western railroad. Starting with locomotive #2120 in 1936, the Y6 class would become the final refinement of the 2-8-8-2 design, and the Y6b is considered the epitome of the compound mallet development. The N&W shops in Roanoke, Virginia gave all Y Class engine and tender axles roller bearings and they used the same outside frame lead truck as the Class A. The trailing truck was also equipped with roller bearings which were fit into an outside frame design. With these improvements, the Y6's cost considerably more than their earlier brethren, but the maintenance records show that these locomotives had a time available for assignment far superior to any of the predecessors. The Y6b had a starting tractive effort in simple configuration of 152,206 pounds. In the compound mode, a tractive effort of 126,838 was achieved. The locomotives delivered 5,500 horsepower. The Y6b locomotive weight was 582,900 lbs with 522,850 lbs directly on the drivers. When the N&W ceased their mainline steam operations in 1959, 50 of the Y6s were still running out serviceable miles in the coal fields waiting for the final order of diesels to replace them. The last of the Class Ys were retired in the summer of 1960.

Locomotive Features -

- ALL-NEW Paragon4 Sound & Control System featuring Rolling Thunder

- Integral Dual-Mode Decoder with Back EMF for Superb Slow Speed Operation in DC and DCC

- Precision Drive Mechanism engineered for continuous heavy load towing and smooth slow speed operation

- Extra Built-in Capacitance for more Consistent Elecrical Pick-up

- Die Cast Locomotive Body with Die Cast Chassis for Heavier Weight and Maximum Tractive Effort

- Rubber Tires for Additional Tractive Effort

- Premium Caliber Painting with Prototypically Accurate Paint Schemes and Road Numbers

- Prototypical Light Operation with Separately Controllable Headlight, Rear Light, and Cab Light

- Many Separately Applied Details such as Handrails, Ladders, Piping, Whistle, and Bell

- Operating Microtrains-compatible Couplers

- Will Operate on Code 55, Code 70, and Code 80 Rail

- Minimum Operating Radius: 9.75 inches

- Accurate Prototypical Sounds for the N&W Y6b 2-8-8-2 Engines

DCC/Sound Features -

- Operates in DC & DCC with improved DC speed control (use DCMaster for DC Sound)

- Built-In capacitor pack to navigate imperfect track

- Capacitor Pack automatically disabled on program track for full compatibility with JMRI Decoder Pro

- Pro Lighting Mode offers individual control of all lights on model

- Switcher Mode for precise low speed control.

- Record & Play Operation - Records and plays back sounds and movements once or repeatedly for automatic operation

- High Resolution Audio

- Quillable Whistle for various whistle lengths and patterns

- Choice of 3 selectable Horns

- Alternate Whistle / Horn where applicable for locomotive with air horn and steam whistle - both the main whistle and alternate can be easily played

- Adjustable bell ringing interval for faster or slower bell

- Numerous user-mappable functions with available keys

- Johnson Bar Sound at Direction Change

- Multiple realistic passenger and crew sounds play on command

- Grade Crossing Automatic Signal

- Automatic Forward / Reverse Signal - When activated, stopping triggers and stop whistle toot. When moving forward from a stopped position, toots twice. When moving in reverse. toots three times.

- Chuff sound intensity varies with load

- Individually adjustable sound volumes for each effect

- EZ Reset Button for quick return to factory default settings

Shell Removal -

To remove the cab and the top of the boiler shell, first disconnect the two handrails on the back of the cab. Next, remove the three screws that hold the shell in place (one is inside the smokestack and the other two are immediately behind the rearmost driverset). Once the screws are out, the shell should lift off fairly readily.

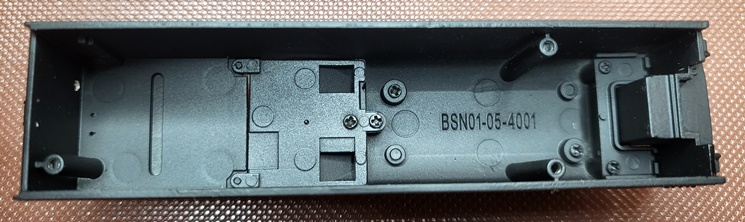

To remove the tender shell, remove the three screws on the bottom that hold it in place. Note that it is not necessary to remove the screws that hold the trucks in place.

Grade: A