Introduced: 2018 (Paragon3 version) and 2024 (Paragon4 and Stealth versions)

These smooth running and fine looking locos all come equipped with factory-installed Paragon3 DCC Sound decoders. They run equally well on analog and DCC layouts (although analog users will need one of BLI's "DC Master" control boxes in order to take advantage of all the sound features). Internal support is provided for BLI's "Rolling Thunder" sound system. Said system consists of a large external subwoofer-type speaker and a receiver that locomotives talk to via radio signals. I've personally never witnessed the Rolling Thunder system in operation, but I guess its purpose is to reproduce the beefy low-frequency sounds that tiny internal locomotive speakers simply cannot render.

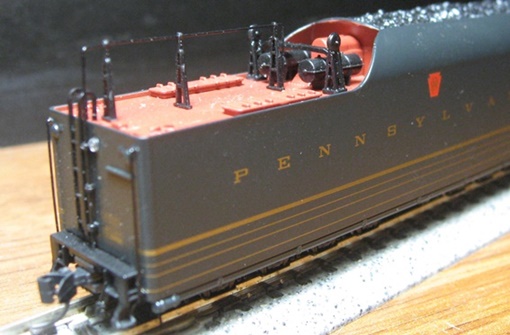

These are gorgeous looking models, with crisp paint and fine detailing -

The locomotive shell is metal (with numerous press-fit plastic detail parts) -

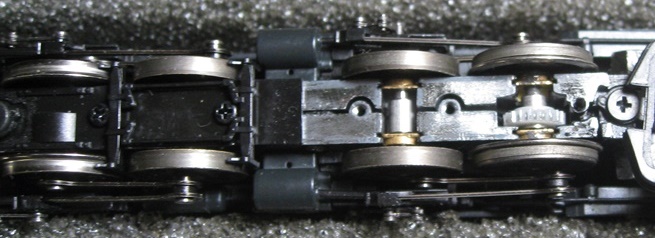

The chassis is metal and split-frame. The motor is an open-sided five-poler with skew-winding. One motorshaft has a large brass flywheel whereas the other has a small white metal "donut-looking thingy". Plastic u-joints connect the flywheel and donut to the wormshafts. The worms seat inside of plastic boxes clipped to the top of the chassis.

Current from the locomotive chassis flows into a PC board screwed to the top of the chassis. Two wires from the PC board transfer current to the motor and an additional two wires transfer current to an LED board mounted inside the front of the shell. Seven wires (for track power, motor control and lighting control) run from the PC board, through the drawbar, and ultimately to the decoder in the tender. The wires to the headlight LED board are distressingly short, so it's difficult to get much separation between the locomotive chassis and the shell. Also, given that the headlight wires are soldered on either end, it appears that one would need to de-solder them in order to completely separate the locomotive shell from its chassis. Conversely, the wires running between the locomotive and the tender are fixed inside of a plug that connects to a socket on the decoder board. So, to completely separate the tender and the locomotive you would remove the tender shell, pull out the wiring plug, and then disconnect the drawbar.

All four drivers provide pickup, although the rearmost pair of drivers is equipped with traction tires and so are probably only marginally effective at collecting current (if they do at all). The pilot is equipped with a Micro-Trains #1015 coupler. A small baggie with a dummy (IE non-operating) knuckle coupler is included in the box. Said baggie also includes a couple of spare traction tires. The drawbar design is similar to the one used by Athearn in their Big Boy and Challenger models. Each end of the drawbar has a small spring hooked to it, which are then looped over posts on the locomotive and tender chasses. Said springs presumably help to keep the drawbar centered. The wheels are blackened and low-profile (IE no problems on Atlas Code-55 rails). All four trucks (pilot, trailing and tender) are sprung.

Current flows from the drivers, to the axles, and then ultimately to the chassis by way of brass bearing blocks that seat inside cutouts in the frame. The pilot and trailing trucks are electrically neutral. The #1 and #4 axles are geared, whereas the inner two driversets are turned solely by the running gear. The drivers are non-articulated (as per the prototype). The center two driversets are blind (IE flangeless). Apart from the brass worms, all gearing is plastic. Gear reduction is approximately 36:1.

The tender chassis is metal (unlike the tender shell, which is plastic). The coupler is a chassis-mounted MTL 1015 -

For DCC-Sound models, the decoder is screwed to four posts inside the tender. Stealth models have a Next18 DCC interface on the DC motherboard. As noted previously, wires to the locomotive are attached to a plug that connects to the front of the board. A second wiring harness plugged into the back of the decoder transfers current to the enclosed speaker and backup light LED board. There aren't any speaker holes in the chassis (or shell), but to be honest, it doesn't really need them. I'm assuming the black wire taped to the top of the decoder board (insulated from said board by a piece of bubble wrap) is the antenna for the Roller Thunder system.

Tender pickup is a bit primitive as compared to the BLI M-1. Instead of all wheels collecting current via low-friction axle-end cups, the T1 uses mid-axle wipers. Consequently, only eight of the wheels provide pickup (with each truck only collecting current from one rail - left-rail on the forward truck and right-rail on the rear truck). Wires soldered to the axle wipers transfer current to the plug on the back of the decoder.

Note that the behavior of the headlight is a little strange (as least as compared to what we're normally used to). When the locomotive is first put on the rails there is no sound and no headlight (regardless of whether F0 is selected or not). The sound comes on once the locomotive starts moving (and stays on until either you mute it with F8 or recycle track power). As for the headlight, that doesn't come on until about three seconds after the locomotive has started moving (and then, like the sound, stays on until you either deselect F0 or recycle track power). The headlight is directional insofar as it will get brighter when moving forward and turn off when moving backward. The backup light only comes on when the locomotive is actually moving backwards. As one might expect, the numberboard lighting is non-directional.

Overall performance is quite outstanding. Pulling power is impressive, with mine comfortably able to haul twenty assorted 85' passenger cars (and probably a whole lot more than that, but that's all I had handy). Out of the box, mine was just a little bit balky. However, that all cleared up after a few minutes of running time (although like pretty much all DCC Sound locos, one does have to be pretty vigilant about keeping the wheels and rails clean). Mine ran smoothly and quietly at all throttle levels (no binding, shimmying, wobbling, rattling, buzzing, grinding, clicking, clanking, or clunking). Slow speed creep is impressive and the top end speed is reasonable and realistic. I didn't have any problems crawling mine through insulated-frog turnouts at yard speeds, so pickup is more than adequate. No problems on narrow (9.75" radius) curves either, although it looks a little odd on curves that sharp. 11" or broader will probably make it happier.

The sound is impressive (at least to my ear), although I've read that it can be improved quite a bit by replacing the stock speaker with something better (a 13x18mm cell phone speaker, for example). But before resorting to that, I'd first try adjusting some of the various decoder CV settings for sound (all of which are delivered with a default value of 128). This is of course quite subjective, but here are some suggested settings - CV135 (whistle)=230, CV136 (bell)=60, CV150 (dynamo)=30, and everything else (chuffs, hiss, etc)=80.

I did run into one QC problem with mine that resulted in the pilot truck mysteriously derailing every few minutes. Not being entirely sure what the problem was, I tried simply removing and reinstalling both of the pilot truck screws. And, lo, that took care of the problem. So, I dunno, maybe one or both of the screws was too tight and preventing the truck from pivoting properly. But beyond that one minor glitch I didn't have any other issues. These really are great locos - both in terms of looks and performance.

FYI, first run boxes incorrectly state "HO Scale" on the side (although the label on the end does say "N Scale"). Documentation included in the box is limited to a list of functions and what they do. If you need a parts diagram or operating instructions you're going to have to visit BLI's website.

Trivia - For a more prototypical look, check out the etched steel front grills made by Keystone Details -

Prototype -

The Pennsylvania Railroad T1 4-4-4-4 may look and sound like an articulated steam locomotive, but it really was a rigid frame locomotive with a second pair of cylinders dividing the drivers, making it a duplex drive locomotive. The design was a successful one and after a trial of two locomotives, the PRR ordered 50 more. The BLI models represent the production locomotives as they appeared in the 1950s.

Locomotive Features -

- Paragon3 Sound & Operation System Featuring "Rolling Thunder" with Authentic Sounds and Prototypical Operation in both DC and DCC environments

- Integral DCC Decoder with Back EMF for Industry Best Slow Speed Operation in DC and DCC

- Precision Drive Mechanism engineered for continuous heavy load towing and smooth slow speed operation

- Premium Caliber Painting with Authentic Paint Schemes

- Prototypical Light Operation with Golden White LED Headlight

- Die Cast Body with Die Cast chassis for Maximum Tractive Effort

- Couplers: Microtrains #1015

- Separately Applied Handrails, Ladders, Whistle, and Brass Bell

- Will Operate on Code 55, 70, and 80 Rail

- Recommended Minimum Radius: 9.75 inches

DCC-Sound Features -

- Operates in DC & DCC (use DCMaster for DC Sound)

- Record & Play Operation - Records and plays back sounds and movements once or repeatedly for automatic operation

- 16-bit Sample Rate for exceptional high frequency sound clarity

- Playback Whistle for multiple whistle lengths and patterns

- Choice of 3 selectable Whistles

- Alternate Whistle where applicable - both the main whistle and alternate can be easily played

- Adjustable bell ringing interval for faster or slower bell

- Numerous user-mappable functions with available keys

- Johnson Bar Sound at Direction Change

- Passenger Station Ambient Sounds - Controlled with Function Key

- Freight Yard Ambient Sounds - Controlled with Function Key

- Lumber Yard Ambient Sounds - Controlled with Function Key

- Farm Ambient Sounds - Controlled with Function Key

- Crew Radio Communications - Controlled with Function Key

- Maintenance Yard Ambient Sounds - Controlled with Function Key

- Demo Mode for display and demonstrations

- Grade Crossing Automatic Signal

- Simple Programming with Integral DCC Decoder

- Automatic Forward / Reverse Signal - When activated, stopping triggers and stop whistle toot. When moving forward from a stopped position, toots twice.

When moving in reverse. toots three times

- Chuff sound intensity varies with load

- Individually adjustable sound volumes for each effect

Shell Removal -

To remove the locomotive shell, unscrew the two small screws at the back end (underneath the cab) and the one small screw just forward of the pilot truck. The shell should lift up and off relatively readily at this point (just be careful with the headlight wiring). To remove the tender shell, unscrew the four screws on the bottom of the chassis. At this point you should be able to lift the shell off. However, there are pieces of tape on the inside of the shell that create a lot of friction and so you may need to pry up on the shell to get it off. It's best to start this procedure from the front by inserting a small screwdriver into the drawbar opening and then prying upwards. Then, gradually work the shell upwards along its entire length. Take your time and be very careful as the sides of the tender are quite thin and fragile. Also, be mindful of the rear of the shell - if you spend all your time lifting up on the front of the shell, the rear corners can get forced into the chassis and possibly break (yeah, don't ask me how I know this).

Grade: A