Introduced: 2019 (Paragon3 version), 2022 (Paragon4 version) and 2023 (Stealth version)

These gorgeous looking and smooth running models are available with or ithout factory-installed DCC Sound decoders (either Paragon3 or Paragon4). They are designed to run equally well on analog and DCC layouts (although analog users will need one of BLI's "DC Master" control boxes in order to take advantage of all the sound features). Support is provided for BLI's "Rolling Thunder" external sound system.

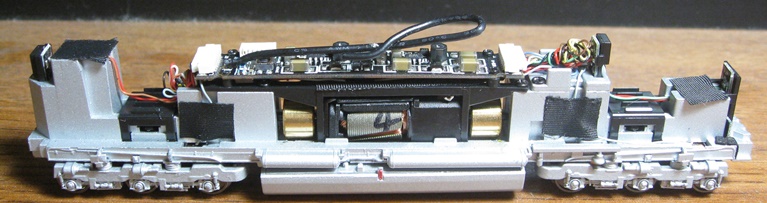

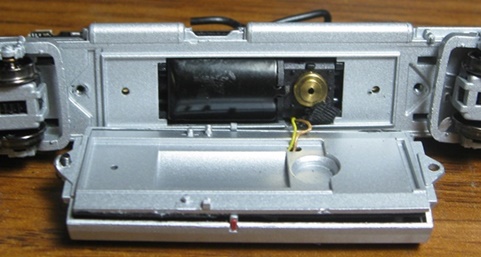

Internally, these models are quite similar to BLI's ES44AC and AC6000CW models of 2018 and 2017 (respectively). The chassis is one big hunk of metal (IE not split-frame). The motor is an open-sided 5-poler with skew-winding. Each motorshaft is equipped with a smallish flywheel. The plastic driveshafts have hex ends on the flywheel side and plastic ball-with-pin / notched-cup U-joints on the wormshaft side. The brass worms mount between bearing blocks that seat inside of slots in the chassis (held in place by plastic clips).

All six axles are geared and all gearing is plastic. The wheels are blackened and low-profile (no problems on Atlas C55 track). The couplers are chassis-mounted Micro-Trains 1015's. There are no traction tires.

A single speaker is provided for DCC-Sound (mounted inside the fuel tank).

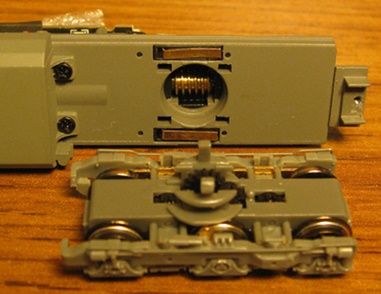

All twelve wheels provide pickup. The axle ends insert into holes (as opposed to dimples) in the axle wipers. Plastic collars on top of the truck gear towers clip inside round openings in the chassis. The trucks pull off and go back on very smoothly and easily. As delivered, the gears are lightly lubricated. Mine came with a few little dangly pieces of flash on the truck sideframes (one of which is visible in the upper lefthand corner of the truck pictured below). Not a big deal to remove, but a bit of a surprise nonetheless. I don't think I've ever seen flash that obvious on a locomotive model before.

On the Paragon3 version, flexible metal contact strips mounted inside the chassis rub up against flat surface contacts attached to the axle wipers (a completely new scheme as compared to previous BLI diesels). Wires soldered to the tops of the chassis contact strips transfer current to the decoder board.

FWIW, I'm told that the reason for the chassis wiper change is that the axle wiper tips on the previous design (pictured below) were susceptible to pivoting off the edges of the chassis contact strips and getting hung up. Not a problem that I've ever had, but evidently at least some people did. Starting with the Paragon4 version, chassis wipers were jettisoned entirely (replaced instead by wires running directly from the axle wipers to the decoder board).

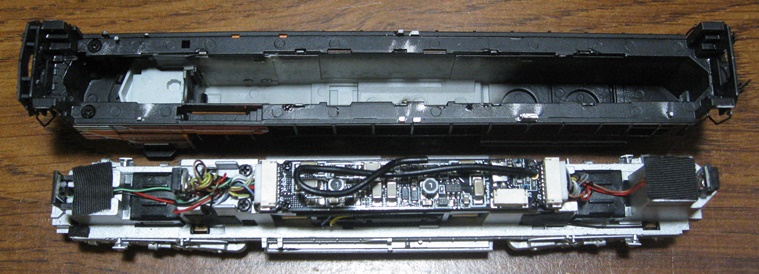

On the sound-equipped models, the decoder board is screwed to a plastic bracket that mounts on top of the motor. The Stealth versions have a Next18 DCC interface on the DC motherboard. Wiring harnesses for track power, lighting control, motor control, and speaker control plug into sockets on either end of the board. Six small pieces of black tape cover up some of the wiring (presumably to prevent it from moving around and causing trouble). A small button on the decoder board allows one to reset the decoder to factory defaults (for situations where writing CV8 doesn't fix the locomotive's problems or where writing CV's isn't an option). I'm assuming the large black wire is the radio antenna for the Rolling Thunder system.

There are two different headlight options (high and low). Three separate LED boards are mounted to the chassis - one at the rear for the backup light, one at the front for the ditchlights (and the nose headlight if it has one), and a third board just forward of the decoder for the high headlight (if it has one) and the cab interior light. AFAIK, there is no provision for having the rear ditchlights light up (for models so equipped). Previous BLI diesels had the LED board for the cab, headlight and numberboards actually mounted up inside the shell (with current then provided by annoyingly short wires running from the chassis into the cab), so this is a small improvement in that regard. However, the ditchlights are barely visible (due to poorly designed light tubing) and the numberboards aren't lit at all, so "one step forward, two steps back" if you ask me.

F0 controls the LEDs for the headlight and backup light. F7 controls the ditchlight LEDs. Once turned on, standard behavior is for all LEDs to be lit when the locomotive is parked. Once you start the locomotive moving, the headlight and backup light become directional (IE, move forward and the backup light turns off). The cab interior light stays on until speed step 3, at which point it turns off (if you don't want a cab interior light at all, set CV208 to 0). An interesting feature of the ditchlights is that they will start strobing (alternately) when the horn is blown. All lighting is white (and excluding the ditchlights, decently bright). When the locomotive is put on the rails, all sounds are off. However, once you start it moving, sound comes on and stays on until you either mute it with F8 or recycle track power.

Performance on these models is quite impressive, although it may take a little bit of tuning before optimum performance can be achieved. As is generally the case with locomotives that have blackened wheels, a certain amount of wheel cleaning may be required before they'll run right. Personally, mine ran great right out of the box, but I've read reports from others who weren't so fortunate.

One other potential source of trouble relates to the axle wipers. For whatever reason, the axles seem prone to squeaking after they've broken in a bit (I've run into the same issue with my last three BLI diesels). The solution here is pretty simple - just apply a little bit of conductalube to the axle ends (where they insert into the holes in the axle wipers). Additionally, it may be necessary to pop the trucks off and clean stray lubricant off of the chassis wipers and the truck contact pads on the Paragon3 version. I had to do this a couple of times during the break-in period. Lastly, track and wheels must be kept spotlessly clean for these models to run properly. As generally seems to be the case with BLI diesels, I have to clean the track every time I want to run one (even if I just cleaned it the day before).

Once suitably tweaked, these are fine running models (be it analog or DCC). Mine runs whisper quiet and super smooth at all throttle settings. Slow speed creep is one-tie-at-a-time and the top-end speed is very realistic (IE not too fast). Mine can creep through insulated-frog turnouts at yard speeds, so no problems with pickup or current conductivity. Pulling power is respectable, with mine able haul 32 assorted 50' freight cars through curves on level track. No problems on sharp (9.75" radius) curves. The sound is robust and nicely rendered (even without bringing a Rolling Thunder system into the equation). Yes, the ditchlight situation is pretty disappointing. But overall, these are terrific looking models that run very well.

Prototype -

The SD70ACe is the successor to the older SD70MAC. Built from 2004 to 2014 in the United States, the SD70ACe was originally designed to comply with EPA Tier 2 locomotive emissions regulations. Beginning in 2012, newly built SD70ACes were EPA Tier 3 compliant. SD70ACes are equipped with EMDs 16-710-G3C-T2 prime mover, rated at 4,300 horsepower (3,200 kW). Later Tier 3 models are rated at 4,500 horsepower (3,400 kW). They are rated at 157,000 lbf (700 kN) continuous tractive effort (191,000 lbf (850 kN) starting). Braking effort is rated at 106,000 lbf (470 kN). Although mechanically similar to earlier SD70 units, the SD70ACe rides on a new underframe and uses mostly new sheet metal above the frame. Electrical cables and air lines have been routed beneath the walkways on opposite sides, allowing easier access for maintenance. Continuing the designs of the SD80 and SD90 series, the radiator on the locomotive is nearly as wide as the cab, the center hood section is a step down below the roofline, and the dynamic brakes have been moved to the rear of the hood. The SD70ACe uses the cab design of late-model SD90MAC-H units, which uses rectangular window glass and is externally different from the two cab variations used on earlier SD70M and SD70MAC units. In 2008, EMD standardized the isolated cab on subsequent SD70ACes after non-isolated cab units were restricted from leading on BNSF Railway due to excessive cab vibration. Purchasers included ArcelorMittal, BNSF Railway, Canadian National Railway, CSX Transportation, Ferromex, Kansas City Southern Railway, Montana Rail Link, Norfolk Southern Railway, CVG Ferrominera Orinoco, Union Pacific Railroad, Quebec North Shore and Labrador Railway, BHP Billiton, and shortline Arkansas and Missouri Railroad.

Locomotive Features -

- Paragon Sound & Operation System Featuring "Rolling Thunder" with Authentic Sounds and Prototypical Operation in both DC and DCC environments

- Integral DCC Decoder with Back EMF for Industry Best Slow Speed Operation in DC and DCC

- Precision Drive Mechanism engineered for continuous heavy load towing and smooth slow speed operation

- Premium Caliber Painting with Authentic Paint Schemes

- Prototypical Light Operation with Golden White LED Headlight

- ABS Body with Die Cast chassis for Maximum Tractive Effort

- Couplers: Microtrains #1015

- Separately Applied Handrails, Ladders, Whistle, and Brass Bell

- Will Operate on Code 55, 70, and 80 Rail

- Recommended Minimum Radius: 9.75 inches

DCC-Sound Features -

- Operates in DC & DCC (use DCMaster for DC Sound)

- Record & Play Operation - Records and plays back sounds and movements once or repeatedly for automatic operation

- 16-bit Sample Rate for exceptional high frequency sound clarity

- Alternate Whistle where applicable - both the main whistle and alternate can be easily played

- Adjustable bell ringing interval for faster or slower bell

- Numerous user-mappable functions with available keys

- Passenger Station Ambient Sounds - Controlled with Function Key

- Freight Yard Ambient Sounds - Controlled with Function Key

- Lumber Yard Ambient Sounds - Controlled with Function Key

- Farm Ambient Sounds - Controlled with Function Key

- Crew Radio Communications - Controlled with Function Key

- Maintenance Yard Ambient Sounds - Controlled with Function Key

- Demo Mode for display and demonstrations

- Simple Programming with Integral DCC Decoder

- Individually adjustable sound volumes for each effect

Shell Removal -

The shell is held to the chassis by the coupler screws, so your first job is to unscrew those and get the couplers (and their clear plastic shims) out of the way. There aren't any "chassis bumps / shell dimples" to deal with, so once the couplers are removed it's just a matter of using small/flat screwdriver to pry the shell up a bit. After that, it should slide up and off readily.

Grade: A (with the caveat re the dim ditchlights)