Introduced: 2018 (Paragon3 version), 2021 (Paragon4 version, High-Hood version) and 2023 (Stealth version)

These smooth running and fine looking models are available with or without factory-installed DCC Sound. They run equally well on analog and DCC layouts (although analog users will need one of BLI's "DC Master" control boxes in order to take advantage of all the sound features). Internal support is provided for BLI's "Rolling Thunder" sound system. Said system consists of a large external subwoofer-type speaker and a receiver that locomotives talk to via radio signals. I've personally never witnessed the Rolling Thunder system in operation, but I guess its purpose is to reproduce the beefy low-frequency sounds that tiny internal locomotive speakers simply cannot render.

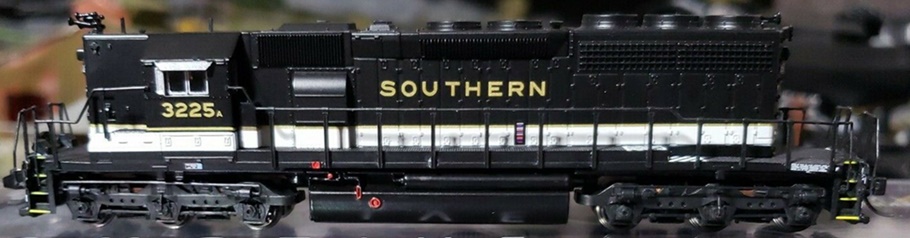

These are very nice looking models, with crisp paint and fine detailing -

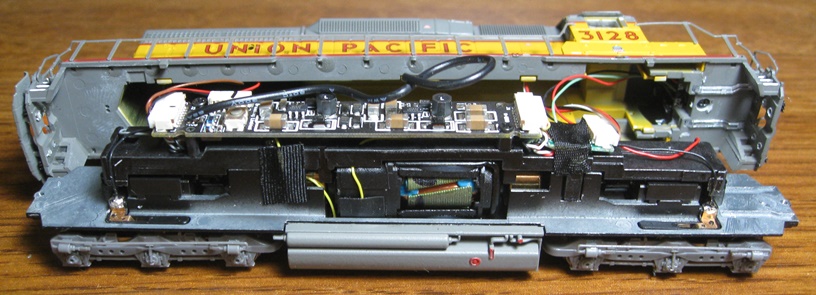

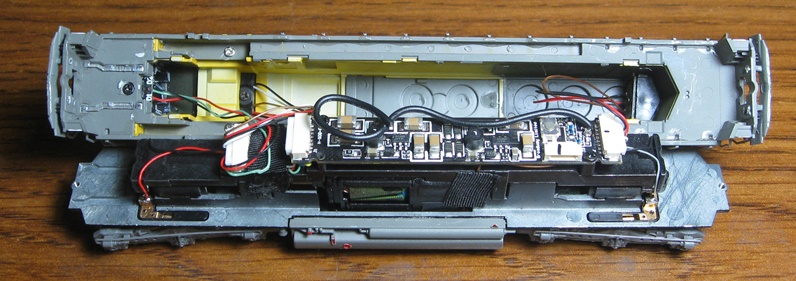

The internal design of the first-run (2018) models is quite similar to BLI's other diesels of similar vintage. The chassis is one big hunk of metal (IE not split-frame). The motor is an open-sided 5-poler with skew-winding. Each motorshaft is equipped with a smallish flywheel. The plastic driveshafts have hex ends on the flywheel side and plastic ball-with-pin / notched-cup U-joints on the wormshaft side. The brass worms mount between bearing blocks that seat inside of slots in the chassis (held in place by plastic clips). I'm assuming the large black wire is the radio antenna for the Rolling Thunder system.

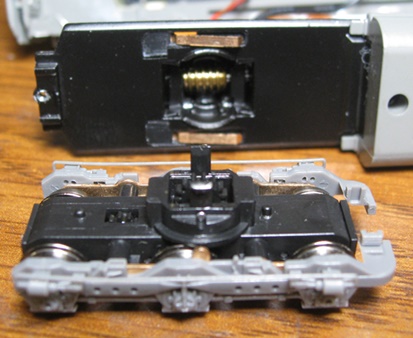

All six axles are geared and all gearing is plastic. The wheels are blackened and low-profile (no problems on Atlas C55 track). A single speaker is provided for DCC-Sound (mounted inside the fuel tank). The couplers are chassis-mounted Micro-Trains 1015's. There are no traction tires.

All twelve wheels provide pickup. The axle ends insert into holes (as opposed to dimples) in the axle wipers. Vertical extensions on top of the axle wipers contact flexible metal strips firmly mounted inside the chassis. Wires soldered to the tops of said metal strips transfer current to the decoder board. Plastic collars on top of the truck gear towers clip inside round openings in the chassis. The trucks pull off and go back on very smoothly and easily. As delivered, the gearing is very lightly lubricated.

For sound-equipped models, the decoder board is screwed to a plastic bracket that mounts on top of the motor. The Stealth versions have a Next18 DCC interface on the DC motherboard. Wiring harnesses for track power, lighting control, motor control, and speaker control plug into sockets on either end of the board. A couple of pieces of black tape cover up some of the wiring (presumably to prevent it from moving around and causing trouble). An LED board for the backup light is wired up inside the rear of the shell. Another board (with individual LEDs for the headlight and ditchlights) is wired up inside the front of the shell. Tubes of light conducting plastic mounted in the shell get light up to the ditchlights. A third wiring harness runs to the cab and provides current for the cab interior and numberboard lighting. A small button on the decoder board allows you to reset the decoder to factory defaults (for situations where writing CV8 doesn't fix your locomotive's problems or you don't have the ability to write CV's at all).

F0 controls the LEDS for the headlight, backup light and numberboards. F7 controls the ditchlight LEDs. Once turned on, standard behavior is for all seven LEDs to be lit when the locomotive is parked. Once you start the locomotive moving, the headlight and backup light become directional (IE, move forward and the backup light turns off). The cab interior light stays on until speed step 3, at which point it turns off (if you don't want a cab interior light at all, set CV208 to 0). An interesting feature of the ditchlights is that they will start strobing (alternately) when the horn is blown. All lighting is white and very bright (except for the ditchlights, which are a bit dim). When the locomotive is put on the rails, all sounds are off. However, once you start it moving, sound comes on and stays on until you either mute it with F8 or pull the locomotive off the rails.

This is probably the finest running BLI locomotive I've encounterd to date. For starters, I was able to take mine out of its box and run it without any sort of preemptive wheel cleaning (or any other tweaks for that matter). Overall, it runs smoothly and quietly at all throttle levels. No stutters, stalls or sound cutouts due to pickup issues. No derailing (even on curves as sharp a 9.75" radius). Slow speed creep is "one tie at a time" and the top end speed is reasonable and realistic. The sound is robust and nicely rendered. My only minor gripe is that they don't pull quite as well as a Kato or Intermountain SD40-2. My BLI unit can only handle about 24 assorted 50' freight cars through curves on level track, whereas my Kato and Intermountain SD40-2's can handle about 30 such cars. But other than that minor deficiency, these are gorgeous looking models that perform admirably well.

Much to my surprise, the internals were changed rather drastically (and rather inexplicably) in the second (Paragon4) production run -

As pictured above, the easily removeable trucks were replaced by complex trucks that are very much like the ones used by scaletrains.com in their diesels (trucks which I have never been able to figure out how to remove). Also gone are the phosphor bronze contacts between the trucks and the chassis (now replaced by wires). And no, I have no idea why these changes were made. Both versions perform equally well, so all they've really done is make them harder to work on.

Prototype -

The EMD SD40-2 is a 3,000-horsepower (2,200 kW) C-C diesel-electric locomotive built by EMD from 1972 to 1989. The reliability and versatility of the 3,000-horsepower (2,200 kW) SD40-2 made it the best-selling model in EMD's history and the standard of the industry for several decades after its introduction. The SD40-2 was an improvement over the SD40, with modular electronic control systems.

Model Features -

- NEW Sound & Operation System FEATURING ROLLING THUNDER with Authentic Sounds and Prototypical Operation in both DC and DCC environments

- Integral DCC Decoder with Back EMF for Industry Best Slow Speed Operation in DC and DCC

- Precision Drive Mechanism engineered for continuous heavy load towing and smooth slow speed operation

- Premium Caliber Painting with Authentic Paint Schemes

- Prototypical Light Operation with Golden White LED Headlight, Rear Light

- ABS plastic body with heavy die cast chassis for maximum tractive effort

- (2) Operating Micro-Trains #1015 or compatible couplers

- Separately applied handrails, ladders, whistle and brass bell

- Will Operate on Code 55, 70, and 80 Rail

- Recommended Minimum Radius: 9.75 inches

DCC/Sound Features -

- Operates in DC & DCC (use DCMaster for DC Sound)

- Record & Play Operation - Records and plays back sounds and movements once or repeatedly for automatic operation

- 16-bit Sample Rate for exceptional high frequency sound clarity

- Alternate Whistle / Horn where applicable for locomotive with air horn and steam whistle - both the main whistle and alternate can be easily played

- Adjustable bell ringing interval for faster or slower bell

- Numerous user-mappable functions with available keys

- Passenger Station Ambient Sounds - Controlled with Function Key

- Freight Yard related radio chatter - Controlled with Function Key

- Lumber Yard Ambient Sounds - Controlled with Function Key

- Farm related radio chatter - Controlled with Function Key

- Crew Radio Communications - Controlled with Function Key

- Maintenance Yard related radio chatter - Controlled with Function Key

- Demo Mode for display and demonstrations

- Simple Programming with Integral DCC Decoder

- Individually adjustable sound volumes for most effects

Shell Removal -

To remove shell, you first have to unscrew and remove the couplers. After that, it's just a matter of sliding the shell up and off. It's a pretty tight fit (what with all the tape stuck to the sides of the chassis), so I use a small screwdriver between the shell and the chassis to gradually pry the shell upwards (working slowly around the shell). Also, be mindful of all the wires running from the decoder to the various LED boards inside the shell.

Grade: A (for both versions)