Introduced: 2023 (BLI version) and 2024 (Minitrix version)

As noted above, Minitrix started importing a slightly different version of BLI's Big Boy in 2024 (presumably for the European market). AFAIK (having never owned the Minitrix model), the only differences between the two are in the couplers and possibly the decoders.

And now, my apologies for shirking my normal duties in this review, but you will not find any in-depth mechanical analysis of BLI's Big Boy here. I had so many frustrating operational problems with the one I purchased that I finally just gave up and sent it back to the vendor for a refund before I even had a chance to take it apart. I'll probably try again with some future production run, but at least for now this is all you're going to get from me -

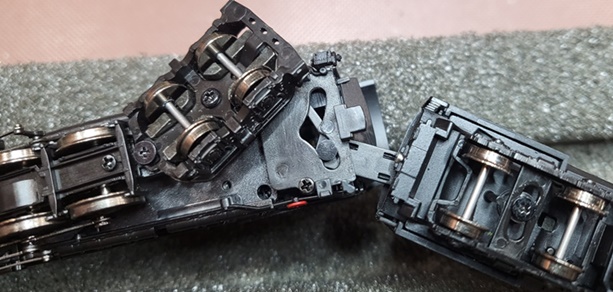

Problem #1 - Derailing. As I was breaking the loco in I noticed that the tender would often run crooked down the track, which I eventually figured out was caused by the rear tender wheels derailing. As pictured below, the drawbar connection is rather overly complex and what I was seeing with mine was that when exiting a curve there would be an audible click accompanied by a noticeable jump by the tender (and with the end result being a derail). It seems to me that the drawbar is getting hung up in the curve-to-straight transition, building up pressure, and then breaking loose with excessive force. And oddly enough, the problem only manifests itself during right (clockwise) turns (and do note that my sharpest curve is 19"-radius, so it's not like I was trying to force this thing through trolly-track curves).

Problem #2 - Inability to handle dips. I have a very small (nigh imperceptable) dip in a section of my Unitrack where a short section of feeder track sits between two long straights. It has never been a problem until now (in fact, I never even knew it was there until now). But, boy oh boy, did the Big Boy ever striuggle with it. Every time through, one of the engines would lose traction and the loco would either slow way down as it passed over the dip, or it would simply stall out with one set of wheels spinning in the air.

Problem #3 - Random stops. Ala my BLI RSD-15, this model likes to take short rests every 15 minutes or so. It doesn't stutter or stall, it just slowly comes to a halt, sits there for a moment, then speeds back up and resumes its journey. I don't know if it's a problem with the pickup scheme, or a problem with the decoder, or a lack of adequate "keep alive" eletronics, but whatever the source of the problem, it seems to plague more than one BLI loco.

I tell ya, I got so frustrated with this thing that after about a week I finally had to pull out my Athearn Big Boy and run that around just to remind myself what a quality runner looks like. Now, maybe I just got a bad example (y'know, assembled on a Friday at 4 PM), and if there was just one problem I might be willing to cut BLI some slack. But given the huge pricetag on these things ($480), I think three dealbreaker problems in one package is pretty much an "Epic Fail" as far as I'm concerned. But as always, YMMV.

Prototype -

Often called the largest steam loco ever made, and certainly a contender for the Worlds Most Famous Locomotive, the Big Boy was forged under some of the most strenuous demands ever placed on a locomotive. The UP Railroad needed a locomotive that could be used to pull a 3,600-ton train over Sherman Hill and the 1.14% grade from Ogden to Wasatch, Utah without the need for helpers. When the design specifications were complete, it was decided on the use of a simple articulated, high speed, 132 ft. long locomotive sporting sixteen 68" diameter drive wheels. What they created was the longest and among the heaviest, most powerful steam locomotive legends in the world. And had not the worker at ALCO chalked Big Boy on the side of the smoke box of one of the 4-8-8-4s under construction, a name that immediately caught on, it is rumored that the name of the type would have been Wasatch, for the mountains they were built to conquer.

There were 25 locomotives fabricated in two different groups. Class 1 were locomotives #4000-4019 and Class 2 was numbered 4020-4024. The first Big Boy #4000 was delivered to Omaha, NE on September 5, 1941. The Union Pacific Railroad's commitment to the Big Boy required them to replace the lighter rail and straighten out many miles of track for clearance as well as to resize elements of their service areas (such as turntable lengths, etc.) for the entire line these locos would run on. The Big Boys demonstrated fantastic strength and speed as they faced these challenges throughout their storied careers. With the total mileage on the Big Boy fleet being approximately 1,000,000 miles for each locomotive, one must say that they earned their reputation. Several examples remain in museums around the country but silently they sit as a visual echo to the thunder that once made them revered throughout the landscape that the Big Boys dominated

Locomotive Features -

- Paragon4 Sound & Control System featuring ROLLING THUNDER

- Integral Dual-Mode Decoder with Back EMF for Superb Slow Speed Operation in DC and DCC

- Precision Drive Mechanism Engineered for Heavy Towing and Smooth Slow Speed Operation

- Operating Smoke Unit with On/Off Switch

- Six Drivers and All Tender Wheels Pick-up Electricity from Track

- Die Cast Locomotive Body with Die Cast Chassis for Heavier Weight and Maximum Tractive Effort

- Rubber Tires on Two Drivers for Additional Tractive Effort

- Premium Caliber Painting

- Prototypically Accurate Paint Schemes and Road Numbers

- Many Separately Applied Details such as Handrails, Grab Irons, Piping, Tender Ladders, Whistle, and Bell

- Prototypical Headlight and Rear Light Operation

- Separately Controllable Cab Light and Lighted Numberboards

- Prototypically Accurate Sounds for the Union Pacific Big Boy

- Operating Microtrains-compatible Couplers

- Will Operate on Code 55, Code 70, and Code 80 Rail

- Minimum Operating Radius: 9.75 inches

- Accurately modeled front end with appropriate aftercooler system for each class

- Accurately modeled 25-C-100 and 25-C-400 tender, appropriate for each class

- Accurately modeled oil tender for #4014 which operates in excursion service today

- Two models painted in attractive two-tone gray paint schemes that the Big Boys never received in real life

DCC/Sound Features -

- Operates in DC & DCC with improved DC speed control (use DCMaster for DC Sound)

- Built-In extra capacitance to navigate imperfect track

- Pro Lighting Mode offers individual control of all lights on model

- Switcher Mode for precise low speed control

- Record & Play Operation - Records and plays back sounds and movements once or repeatedly for automatic operation

- High Resolution Audio

- Quillable Horn for various whistle lengths and patterns

- Choice of 3 selectable Horns

- Alternate Whistle / Horn where applicable for locomotive with air horn and steam whistle - both the main whistle and alternate can be easily played

- Adjustable bell ringing interval for faster or slower bell

- Numerous user-mappable functions with available keys

- Multiple realistic passenger and crew sounds play on command

- Grade Crossing Automatic Signal

- Automatic Forward / Reverse Signal

- Prime Mover sound intensity varies with load

- Individually adjustable sound volumes for each effect

- EZ Reset Button for quick return to factory default settings

Shell Removal -

Don't know, don't care.

Grade: F (Epic)