M-1b -

M-1b -

Introduced: 2016 (Paragon2 version), 2017 (Paragon3 version) and 2024 (Paragon4 and Stealth versions)

Originally announced in 2005 (by Precision Craft Models), these models became something of a running joke amongst N-scalers as the delivery dates kept getting pushed back year after year (after year... after year... after year...) Seriously, it was the very definition of model railroading vaporware. Fortunately, PCM (now BLI) persevered and eventually did release what turned out to be one of the all-time greats of N scale steam. As pictured above, these models are available in both pre-war (M-1a) and post-war (M-1b) configurations (the differences between the two boiling down to minor variations in some of the detailing).

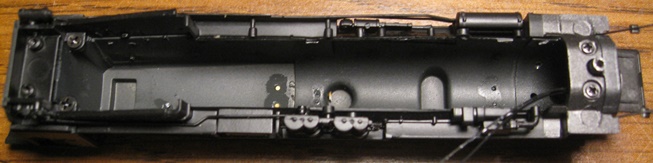

The locomotive shell is metal (with numerous press-fit plastic detail parts) -

The locomotive chassis is all-metal and split-frame -

According to BLI, the flywheel-equipped motor is a five-poler with skew-winding. However, since it's a closed-sided can, I don't really have any way of verifying that. So, we'll just have to take their word for it.

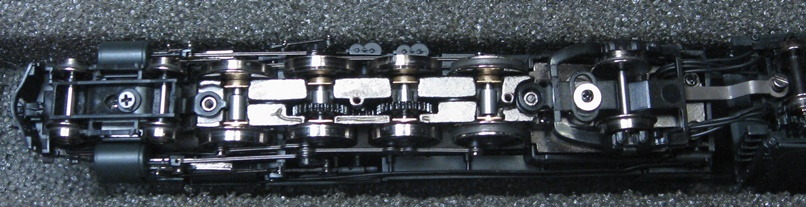

Six of the eight drivers provide pickup (the rear-most driverset being equipped with traction tires). Current flows from the drivers, to the axles, and then ultimately to the chassis by way of brass bearing blocks that seat inside cutouts in the frame. The pilot and trailing trucks are electrically neutral. The center two driversets are geared, whereas the forward and rear sets are turned solely by the running gear (note that the running gear is not attached to the #3 drivers). The center two driversets are blind (IE flangeless) as per the prototype (which probably explains why the traction tires wound up on the non-geared rear drivers). Apart from the brass worm, all gearing is plastic.

Current from the locomotive chassis flows into a PC board screwed to the top of the chassis. From there, a pair of wires transfer current back to the tender PC board. Two wires from the tender PC board transfer current to the motor and four wires for headlight control transfer current to the locomotive PC board. An additional two wires from the locomotive PC board transfer current to the LED mounted inside the headlight housing. Given that the headlight wires are soldered on either end, it appears that one would need to de-solder them in order to completely separate the locomotive shell from its chassis. Conversely, the eight wires running between the locomotive and the tender are fixed inside of a plug that connects to a socket on the tender PC board. So, to completely separate the tender and the locomotive you would remove the tender shell, pull out the wiring plug, and then unscrew the metal drawbar.

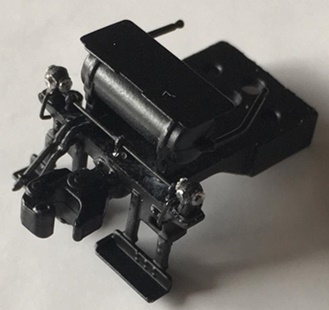

A Micro-Trains #1015 coupler comes screwed to the tender chassis -

Wheels are low-profile (IE no problems on Atlas Code-55 rails). All four trucks (pilot, trailing and tender) are sprung.

The pilot is equipped with a dummy (IE non-operating) knuckle coupler. In addition to being non-operational, said pilot coupler is also very small. So, probably not particularly useful for double-heading. Starting with the second (2017) production run, an ala carte pilot with a larger coupler was included in the box for those desiring a more practical pilot coupler -

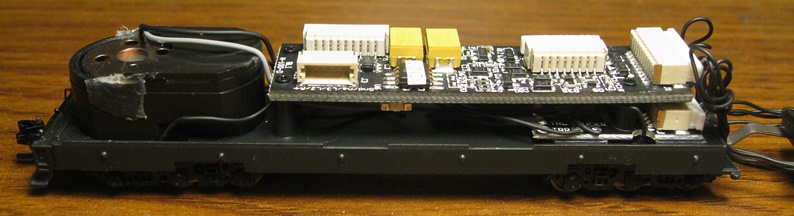

The tender chassis is metal (as opposed to the shell, which is plastic) -

All twelve tender wheels provide pickup by way of low-friction axle cups. Wires soldered to the axle wipers transfer current to the PC board inside the tender (a somewhat suboptimal scheme, since mine was delivered with one of its truck wires already de-soldered). For the DCC Sound versions, the decoder is screwed to four posts inside the tender. The "Stealth" versions have a Next18 DCC interface on the DC motherboard. A pair of 9-pin plugs (with four wires each) connect the tender PC board to the decoder. Wires from the decoder transfer current to the enclosed speaker. There aren't any speaker holes in the chassis (or shell). But to be honest, it doesn't really need them.

The tender is equipped with backup and marker light details, however they are non-functional (not too surprising, given their miniscule size). They do come with blingy little gems that at least provide the illusion of lighting.

Overall performance is virtually perfect in every way (be it on DCC or DC). Pickup and current conductivity are flawless (even creeping through insulated frog turnouts). Throttle response is fine at all levels. Slow-speed creep (at speed step 1) is one-tie-at-a-time, whereas the top-end speed does seem a bit excessive (of course the latter can be adjusted by simply changing the CV settings in the decoder). The motor and moving parts synch up nicely, making for smooth and whisper-quiet performance at all speeds (no wobbling, shimmying, hitching, buzzing, growling or any of that other bad steam nonsense). Pulling power is strong, with mine comfortably able to haul 40+ assorted freight cars through curves on level track.

Despite BLI's claims that these models can handle 9.75"-radius curves, I found that the drivers on mine would consistently derail on curves that sharp. No problems on 11" curves, though. And apart from the sharp curves, I didn't have any other problems with any of the wheels derailing. I also didn't have any problems with any of the wheel gauging being too tight (a common malady with BLI locomotives, and one that often leads to problems through turnouts).

The white headlight is directional and super bright (and also adjustable, should you find it too blinding). The sound is astonishingly beefy for N scale, giving even Athearn's Challengers and Big Boys a good run for their money. The whistle in particular is really impressive. As delivered, the sound is probably going to be a bit too loud for some people. But once again, all easily adjusted via CV settings. Note that if your intention is to operate one of these on a DC layout, you will need one of BLI's "DC Master" boxes to invoke the non-automatic sound effects (said box also allows non-DCC users to make decoder CV changes).

The only minor issue I noted with mine was a very slight eccentricity in the rotation of the TT-equipped drivers. It's not anything you would ever really notice under most circumstances, but it did become evident when I tried to hook up 50 cars. Basically, the rubber doesn't quite meet the road 100% of the time (resulting in a little bit of slipping at extremely low speeds). And although it becomes pretty much a non-issue once you throttle up to higher speeds, it does seem to at least bear mentioning. Overall though, these are flat out gorgeous looking models that run every bit as good as they look. Kudos to BLI for finally seeing this seemingly never-ending project through to a successful completion.

Prototype -

In 1930, the celebrated success of the Pennsylvania Railroad's M1 Mountain-type locomotives prompted the PRR to order 100 more locomotives of the 4-8-2 wheel arrangement. The new locomotives became the M1a class and had a longer wheelbase than the M1's due to the addition of the Worthington feedwater heater. They also received new larger tenders, class 210F75, which became known as the coast-to-coast tenders.

The first 50 M1a locomotives, #6700-6749, were built by Baldwin. The Juniata Shops, which became knows as the "Altoona Works," built the next 25 M1a's numbered 6750-6774, and the remaining 25 M1a's were built by Lima and were numbered 6775-6799. Starting in 1946, 41 of the M1a's received further improvements by increasing the boiler pressure and adding circulators to the firebox. The improved M1a's became the M1b class. The best way to tell them apart is to look for the circulators on the firebox just above the running boards. The circulators are those round objects in a diagonal line that look like wash-out plugs.

The PRR M1a/b's were considered to be the finest of the PRR's steam locomotives. They were designed as dual service locomotives, hauling passenger trains and also seing duty in general freight service. And in the end, they even hauled the heavy ore trains, which there were not originally intended to pull. They did it all in style!

Locomotive Features -

- ALL-NEW Paragon2 (or Paragon3) Sound & Control System

- Integral DCC Decoder with Back EMF for Industry Best Slow Speed Operation in DC and DCC

- Motor Type: 5-Pole Can with Skewed Armature & Fly Wheels

- Authentic PRR M1a Sounds (on sound-equipped units)

- Premium Caliber Painting with Authentic Paint Schemes

- Prototypical Light Operation with Golden White LED Headlight

- Beautifully Detailed, Accurately Modeled Locomotive

- Separately Applied Details such as brass bell, grab irons, and ladders

- Constant Intensity Directional Lighting

- Locomotive Composition: ABS plastic with Die Cast Chassis

- Tender Composition: ABS plastic with Die Cast Chassis

- Locomotive Length: 6.5 inches

- Tender Length: 3.8 inches

- Coupler: Microtrains #1015

- Recommended Minimum Radius: 9.75 inches (but really, 11" is more realistic)

DCC-Sound Features -

- Operates in DC & DCC (use DCMaster for DC Sound)

- Record & Play Operation - Records and plays back sounds and movements once or repeatedly for automatic operation

- 16-bit Sample Rate for exceptional high frequency sound clarity

- Playback Whistle for multiple whistle lengths and patterns

- Choice of 3 selectable Whistles

- Alternate Whistle where applicable - both the main whistle and alternate can be easily played

- Adjustable bell ringing interval for faster or slower bell

- Numerous user-mappable functions with available keys

- Johnson Bar Sound at Direction Change

- Passenger Station Ambient Sounds - Controlled with Function Key

- Freight Yard Ambient Sounds - Controlled with Function Key

- Lumber Yard Ambient Sounds - Controlled with Function Key

- Farm Ambient Sounds - Controlled with Function Key

- Crew Radio Communications - Controlled with Function Key

- Maintenance Yard Ambient Sounds - Controlled with Function Key

- Demo Mode for display and demonstrations

- Grade Crossing Automatic Signal

- Simple Programming with Integral DCC Decoder

- Automatic Forward / Reverse Signal - When activated, stopping triggers and stop whistle toot. When moving forward from a stopped position, toots twice.

When moving in reverse. toots three times

- Engine sound intensity varies with load

- Individually adjustable sound volumes for each effect

- EZ Reset Button for quick return to factory default settings

To remove the locomotive shell, unscrew the two small screws at the back end (underneath the cab) and the one small screw underneath the pilot truck. Next, free the handrails from the pilot. The shell should lift up and off relatively readily at this point (just be careful with the headlight wiring). To remove the tender shell, insert four toothpicks (or whatever) between the chassis and the shell. This will free the dimples in the shell from the small bumps in the chassis, allowing you to then lift the shell up and off.

Grade: A