Introduced: 2005 (USRA 2-6-6-2) and 2010 (C&O H-4 2-6-6-2)

Apart from the different tenders and the H-4's DCC features, these two models are virtually identical. So, to save myself a bit of time I'm going to cover them both here.

Bachmann's USRA Mallet has a bit of a spotty reputation - some people love them, and some people love to take hammers to them. Overall, they're great looking models with a lot of fine detailing. However, they do have a couple of performance issues that may scare some people away (more on that shortly).

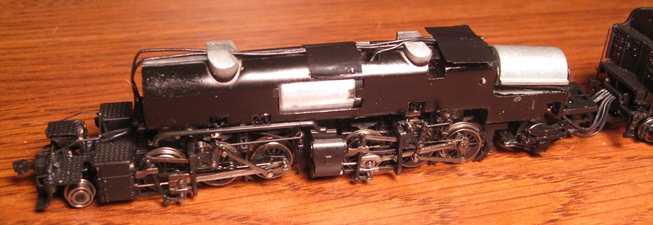

The chassis is all-metal, split-frame and kind of lightweight (given its size). Bachmann advertises the can motor as being a skew-wound 5-poler. However, I've seen pictures of one dismantled and it's actually a straight-wound 3-poler. The center pair of drivers on each engine is geared (with all gearing being plastic). All the rest of the drivers are turned by the cranks. All twelve drivers provide pickup (no traction tires). All eight tender wheels provide pickup as well (with current transferred to the locomotive chassis by way of a couple of stiff wires on the plastic drawbar assembly). Directional lighting is provided by a filament bulb equipped PC board mounted to the front of the chassis (another bit of false advertising, as Bachmann claims the headlight is an LED). There is no lighting in the tender. The pilot is equipped with a non-operational knuckle coupler, whereas the tender has a chassis-mounted Rapido-style coupler. Wheels are blackened (with "white-wall" edges) and low-profile (no problems on Code-55 rails).

These locomotives tend to be billed as "DCC-Ready", but decoder installation isn't as simple as dropping in a PC board replacement or connecting up an NMRA plug. What Bachmann has provided is space inside the engine for a decoder (the removable weight back by the cab), as well as providing wiring leads for track power, motor and lighting all in the same general vicinity.

I really like Bachmann's tender drawbar design (vis'a'vis connecting it up to the locomotive). The oblong post on the locomotive keeps the drawbar firmly attached when handling the locomotive. And disconnecting it is simply a matter of rotating it 90 degrees (at which point it'll just pop off).

Overall performance on these models is decent (if unspectacular). Throttle response is smooth, it doesn't wobble, slow speed performance is respectable, and it doesn't have any problems staying on the rails - so no complaints about the pickup, the cranks, the motor, or the wheels. Owing to the articulated drivers, these models have no problems on curves as sharp as 9.75" radius.

On the downside, these are not a exceptionally strong pullers (particularly for big ol' Mallets). Mine can handle maybe 15-20 freight cars on level track (and perhaps half that on a grade). Any more than that and the drivers are slipping. No, not horrible. But then again, not overly impressive either. I'm told that finding places for additional weight (or adding after-market traction tires) will go a long way towards improving the pulling characteristics. On the nitpick front, I'm not real impressed with the whole "whitewall tire" thing. That white paint is very fragile and flakey, and inevitably will start coming off the minute you start running your Mallet (and consequently, start to look a bit frowzy).

Nitpicking aside, my main gripe with these models is the fact that they're just plain noisy (and unpleasantly noisy at that). I'm not sure what the source of all the racket is exactly, but all the ones I've tested have generated the same combo platter of labored buzzing and grinding sounds at anything above yard speeds. And despite many hours of running, I didn't notice any appreciable reduction in the noise. So yeah, this model is not without its issues. Still, if you just gotta have a USRA 2-6-6-2, this is the only game in town. Fortunately, as of this writing (2009), these models are available at huge discounts (around $70 on eBay). And at those kinds of prices, I think some of the minor deficiencies could probably be overlooked. Having said that, beware of first-run Mallets. I'm told that those had some serious QC problems. In other words, try before you buy (if at all possible).

In 2010, Bachmann released a "new" 2-6-6-2 (their C&O H-4). Externally, the differences boil down to a new tender, slightly altered valve gear, and various changes to the shell detailing (ala the prototype). Internally, the basic chassis / mechanism is pretty much identical to that of the USRA 2-6-6-2 -

The new tender comes with Bachmann's McHenry-esque automatic knuckle coupler, a working back-up light, and a preinstalled "dual mode" DCC decoder. A harness / plug arrangement runs from the tender to the engine for pickup, motor control, and lighting. Due to the Vandy tender's funky "barrel" shape, there is no provision for a speaker -

Performance on this new version is quite outstanding. I'm not exactly sure what it was that Bachmann changed, but the noisiness of the USRA version has definitely been addressed here, as these things run absolutely smoothly and quietly in both DC and analog modes. On the down side, pulling power is still fairly mediocre (20-25 cars on flat track, and a bit less on grades). I'm assuming the slight increase in pulling power (over the USRA) is mainly due to the smoother running mechanism. Still, these are extremely fine running models that most people should be quite happy with. Those with large layouts who want to pull super-long trains will probably want to check into adding traction tires or using "Bullfrog Snot" (no, I'm not kidding, google it).

Here's what Bachmann has to say about the C&O H-4 -

C&O H-4 Articulated 2-6-6-2 is now available in 4 C&O road #'s plus painted/unlettered. Fully articulated loco features Vandy VC12 Tender and DCC-On-Board ... the latest in the growing Bachmann N Scale Spectrum line-up. 150 H-4s were built at Schenectady and Richmond between 1912 and 1918 for the C&O. Individual H-4 batches had adhesion weights ranging from 358,000 to 364,900 lb. You can control the direction, speed, and lighting of this locomotive using Bachmann's E-Z Command� or any NMRA-compliant DCC system. This Bachmann loco is also 100 percent backwards-compatible with standard DC (non-digital) railroad layouts.

To remove the locomotive shell (either version), use a couple of small screwdrivers to spread the sides apart back by the cab. The shell should lift up and off fairly readily at that point. To remove the USRA tender shell, one must first remove the truck screws. Then use a screwdriver to separate the tender body from the chassis (at which point it should pop off). To remove the Vandy tender shell, first remove the chassis screw behind the rear truck. Next, remove the forward tender truck and then unscrew the (now revealed) chassis screw forward of said truck.

Grades: B (for the USRA) and A (for C&O H-4) - with the aforementioned caveats

USRA 2-6-6-2 reviewed 11/05 Model Railroader ("This smooth-running USRA 2-6-6-2 is a compact articulated locomotive that's capable of operating on curve radii as sharp as 9". It's also Bachmann's first N scale articulated locomotive. The N scale 2-6-6-2 follows the same USRA prototype as the firm's HO model... The Spectrum model closely follows the dimensions in USRA drawings... The 2-6-6-2 model's instruction sheets include three pages of exploded isometric drawings that show how it's built. One of these sheets provides details and a step-by-step procedure for installing a decoder in the boiler. Part of the cast-metal boiler weight is removable to make room for a decoder. The model has a die-cast metal chassis and a detailed plastic boiler shell, cab, and tender. Several tiny plastic latches and snap lugs hold the boiler on the chassis. The cab interior has a detail backhead and seats. Many of the detail parts are press-fitted...

"This 2-6-6-2's mechanism has a 12-wheel drive that's similar to what's inside most of today's diesel drives. Its skew-wound can motor, flywheels, main bearings, and worm shafts are clamped between the die-cast halves of the boiler weight. Each six-drivered engine functions as a cast-metal truck with a vertical gearbox. A warm gear on top of each gearbox engages a concealed worm as each engine is snapped into the weight assembly. Both engines swivel and rock slightly under the boiler to ensure that all of the drivers contact the rails for maximum traction and electrical pickup. This double-truck design allows the model to negotiate a 9"-radius curve and reduces the boiler overhang at both ends... All 12 drivers and all of the wheels on both tender trucks pick up electricity. The current from both rails passes through the locomotive chassis to the tender via an insulated drawbar with contacts that bear on a split drawbar pin. A USRA long tender with Andrews trucks is included. It has a removable coal load in the bunker. A Rapido-type coupler is body mounted at the rear... The body is mounted on the plastic floor with pairs of lugs, front and rear. A cast weight is concealed inside. All of the engine and tender wheels have NMRA RP-25 contours and match the standards gauge. Our sample started smoothly and operated quietly at normal operating speeds and at the slow drag speeds typical of their prototypes. The drawbar pull is equivalent to only 16 cars... This is a good-looking and a fine-running model of a medium-size articulated locomotive... C&O, NYC&SL, W&LE. $275")

H-4 2-6-6-2 reviewed 08/10 Model Railroader ("The H-4 Mallet is available as an N scale ready-to-run model. As with the HO version, Bachmann modified its United States Railway Administration 2-6-6-2 to resemble an H-4. The model includes a dual-mode DCC decoder that operates on direct current and Digital Command Control layouts but doesn't feature a sound system.

The locomotive boiler, cab, and tender are plastic and have many separately applied detail parts. These include the bell, whistle, handrails, air pumps, and much of the locomotive piping. The N scale H-4 has a detailed cab interior with painted walls and a molded boiler backhead. The model's motor and flywheel are inside the locomotive boiler. Two worms transfer power from the motor to the second axle on the front and rear engine. The siderods turn the other drivers.

The Mallet has a die-cast metal locomotive frame. The front and rear engines are hinged. The model has a 9" minimum radius but looks better on a 15" or greater radius curves. The locomotive and tender weigh 4 1/2 ounces and are permanently tethered. Wires run from the front of the tender to the rear of the cab. The DCC decoder is accessed by removing the tender's coal load. The drawbar between the locomotive and tender is attached with two screws. Copper contacts run along each side of the drawbar.

The mechanism performed smoothly on a DC test track. The model accelerated from 2 scale mph at 5 volts to 62 scale mph at 12 volts. This top speed is higher than that of the prototype. Both the headlight and backup light are light-emitting diodes (LEDs). The Bachmann N scale Mallet doesn't exactly match a prototype C&O class H-4. However, it provides an option for steam-era fans to add an articulated locomotive to their rosters.")