Dash 8-40C

Dash 8-40CW

Dash 8-40C

Dash 8-40CW

Introduced: 2009 (first version) and 2022 (DCC-Sound version)

These models share the same basic chassis / mechanism. And apart from minor variations in detailing, share very similar shells as well.

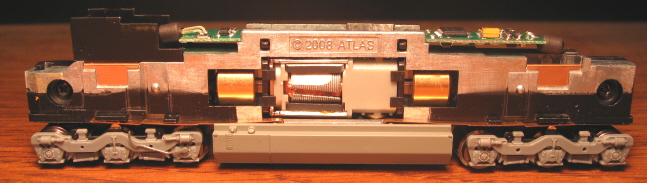

The mechanism sports all the features one normally associates with "modern" Atlas diesels - IE, split-frame / all-metal chassis, 5-pole / skew-wound "scale speed" motor with dual flywheels, low-friction drive, bi-directional "white" LED lighting, all-wheel drive and pickup (no traction tires), blackened / low-profile wheels, shell-mounted Accumate couplers, all-plastic gearing, etc. The chassis is fully DCC-Ready (and, in fact, available with factory-installed decoder).

An interesting new feature on some of these models is the black paint applied to the chassis (as pictured above). Atlas hasn't mentioned it in any of their news releases, but speculation is that it's simply there to make the chassis less visible. In any case, it doesn't seem to interfere with conductivity, so no worries. The odd thing is that not all models have said blackening. Why? Only Atlas knows for sure, but maybe because it works better with some paint schemes than others?

Both versions feature separate window shade and snowplow details (to be installed by the modeler). The wide cab (CW) version comes with working ditch lights (a new feature for Atlas) -

Light is generated by tiny LEDs mounted on a tiny PC board, which is in turn mounted to the front of the chassis. Light is routed to the ditch lights via light conducting plastic mounted inside the shell. Current is provided by wires running back to the decoder / main PC board. The DCC versions have the added feature of strobing ditchlights. However, one (presumably) unwanted side affect of all this extra lighting is the fact that it's clearly visible through the forward door window -

Additional consternation has been registered over the fact that the wide cabs don't seem to mesh very well with the rest of the shell. Initial reports suggest that some (or all) of the wide cabs are missing a number of clips (which would otherwise be holding them more snugly to the sidesills) - one on the front and/or two on the sides (just forward of the battery boxes). In the case of the side clips, it looks like maybe they were omitted as part of a mid-stream design change (IE, holes are there in the sill, but no corresponding clips on the cab). As for the forward clip, these appear to be prone to breaking off - with numerous reports of them being delivered either bent, cracked, or completely missing.

The resulting gaps around the battery boxes (or whatever they are) vary, depending on the state of the forward clip. Personally, I don't think it's that big of a deal (in fact, I doubt that I would've even noticed the "problem" had it not been brought to my attention by others). Still, it does seem to bother some people.

Another minor QC problem reported with the first run of CW's is the excessive use of glue inside the cab (not something you'd notice unless you were trying to dismantle the locomotive for painting purposes). According to Atlas, all these issues were due to problems at the factory and should be addressed in future production runs.

On the performance side these models are perfect in every way - smooth, quiet, flawless pickup and throttle response, exceptional pulling power, etc. In fact, these may well be the quietest diesels ever to come out of Atlas. Apart from the wheels clacking along the track, my Dash 8C's run virtually sans sound.

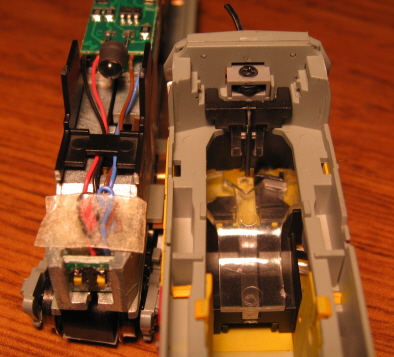

In 2021, the internals were completely redesigned to include support for an ESU LokSound DCC-Sound decoder and accompanying speaker. Analog versions were also part of this release. Instead of using screws and hex nuts to hold the chassis halves together, this new version uses plastic clips on either end of the chassis (the fuel tank and motor saddle also contribute to holding things together) -

Gone are the chassis contact strips that the truck axle-wipers used to rub up against (an Atlas staple since the 1980's). Instead, small wires are soldered to the axle-wipers on the one end and to cylindrical metal plugs (which insert into holes in the chassis) on the other. Note that the plugs are rather tight-fitting, so it's best to push them out from the inside (as opposed to trying to pull them out from the outside).

The rest of the internals are more or less the same as before. A five-pole / skew-wound motor spins dual flywheels. In turn, the flywheels spin plastic shafts with notched-cups on the worm side. Said cups spin little ball-and-pin connectors on the wormshafts. Bearing blocks inside of notches in the chassis hold the brass worms in place. A long plastic shield is clipped to the top of the chassis (dunno why - but maybe to prevent short circuits between the decoder and chassis?).

I particularly like the way the circuit boards (and contacts thereto) have been redesigned. Very similar to IMRC's SD40-2 of 2017, metal contacts on the motor saddle transfer current from the main PC board (or decoder) to the motor and to the speaker mounted inside the fuel tank (note that even the non-sound locos come with a speaker). Unlike previous Atlas locos, the main PC board slides in and out of its chassis slots without requiring that one first partially disassemble the chassis (a nicety that Kato has offered for years). The design and placement of the new PC board contacts is also an improvement over previous Atlas diesels (where getting the motor contacts to line up with the contact pads on the PC board was admittedly a bit "hit and miss").

All twelve wheels provide pickup, all six axles are geared, and all gearing is plastic. The wheels are blackened and low-profile. The trucks and fuel tank appear to be the same as on previous versions. Note that speaker holes in the fuel tank aren't really required since the speaker is positioned such that sound projects upward rather than downward.

The shells are all plastic and include separate detail parts for the windows, numberboards, handrails, cab, sidesills, cut lever, and horn. Couplers are shell-mounted Accumates.

Performance on this new version is every bit the equal of its predecessors. Out of the box, I didn't have any problems with the wheel-blackening causing any sort of jitteriness. They run very quietly, throttle response is smooth, pickup is flawless, slow speed creep is "one-time-at-a-time" and the top-end speed is realistic (IE, not too fast). Pulling power is strong, with mine comfortably able to haul thirty assorted 40' freight cars through curves on level track. No problems with any of the wheels derailing (even on 9.75" radius curves). Overall, just really superb looking and running models.

The sound on the DCC-Sound versions is well rendered and nicely beefy. And for a change, the default settings for volume are quite reasonable. I didn't notice any difference in performance when operating mine with an analog powerpack (IE, they run equally well using DCC or DC control). As seems to be typical with DCC-Sound models these days, the decoders in these locos are programmed to go through a rather protracted sequence of "start up" shenanigans before they start moving (and with similar behavior when slowing down). To eliminate this nonsense (if you're so inclined), simply set CV124 to 0. Also note that the default behavior is for the sound to be off (IE, put the loco on the rails and it won't make a peep). To turn sound on, hit F8.

Prototype information (Dash 8-40C) -

First built for Union Pacific in the late 1980s by General Electric, the DASH 8-40C diesel locomotives were identified by an enlarged exhaust stack and the mounting of the dynamic brake grids in a square-like unit behind the cab, which housed an enlarged equipment blower fan. These six-axle, 4,000 hp engines are still in service today in North America.

Prototype information (Dash 8-40CW)

The 4,000hp Dash 8-40CW was produced by General Electric between 1989 and 1993 as a follow-up to the successful Dash 8-40C locomotive. The most distinguishing feature of this model was the introduction of GE's version of the wide-nose North American Safety Cab. This style of cab would become a common sight on railroads across the country. Four major railroads purchased the Dash 8-40CW in fairly large quantities, including Conrail, CSX, Santa Fe and Union Pacific. Most of these units are still in regular mainline and heavy-haul freight service today. Due to various mergers, they can also be seen operating for new owners Norfolk Southern and BNSF.

Standard Features -

- Separate coupler cut lever

- Directional lighting

- Golden white LEDs

- Painted safety rails

- Blackened metal wheels

- Dual flywheel equipped 5-pole skewed armature motor with a low friction mechanism

- Factory-installed AccuMate magnetic knuckle couplers

DCC-Sound Features -

- Supports all DCC-programming modes

- DCC includes RailCom and RailComPlus, with 14, 28 or 128 speed steps and with 2-digit and 4-digit addressing

- Flexible mapping of function keys F0 to F28

- A total of 6 DCC function outputs are available, and all can be function mapped (disable, brightness, light effects) individually

- Follows all NMRA DCC standards and recommended practices

- Over 20 sound effects are available, including engine start-up and shutdown, prime mover sounds through all eight notches, bell, air horn, air compressor, dynamic brakes and more

- There are up to 16 user-selectable horns, 2 user-selectable bells, and 2 user-selectable synchronized brake squeals

- Equipped with ESU’s Exclusive “Full Throttle” features for ultimate realism in prototype running

Shell removal -

Simply take hold of the shell with one hand and the fuel tank with the other, then just wiggle the shell up and off.

Grade: A (for all)

Reviewed 11/09 Model Railroader - ("N scalers who model the modern day should be happy with Atlas' new release, General Electric's Dash 8-40CW road engine. Atlas' offering is a well detailed, crisply painted model with a smooth, flywheel-equipped drivetrain and an optional DCC decoder. Atlas captures [the look of the prototype] with a finely molded plastic body shell that matches the dimensions of prototype drawings in the September 1997 issue of Model Railroader.

"The flexible plastic handrails are two N scale inches in diameter. Other details include the separately applied bell and horns, cab sunshades, m.u. hoses, coupler cut levers, and wire nose grab irons. The magnetic knuckle couplers are body-mounted, so I was able to lift off the shell without having to remove any screws. In the middle of the split die-cast metal frame is an open-frame, five-pole, skew-wound motor with dual brass flywheels. Power is transmitted to the middle axles of both trucks by brass worm gears, and gears on those axles drive the other wheels. All 12 chemically blackened metal wheels also pick up electricity. The DCC decoder rests in a recess on top of the frame. Plastic light rods conduct light from light-emitting diodes (LEDs) on both ends. A small separate circuit board on the front of the frame has two surface-mount LEDs that, through a similar arrangement, illuminate the ditch lights. These can be controlled with the DCC throttle to be on, off, or blink alternately.

"I tested the locomotive both under direct current and Digital Command Control. In DC, the locomotive started moving about 5 volts (V), rolling at a respectably slow 3 scale mph. At 12V, the model topped out at 124 scale mph, considerably higher than the locomotive's 70 mph upper limit. When I tried the model in DCC, it didn't start moving until the throttle reached speed step 7. After I programmed the decoder's starting voltage ( Configuration Variable 2) to 55, it rolled steadily at 5 mph at speed step 1. At speed step 28, it reached 98.5 mph. I also tried it with the throttle set to 128 speed steps, which gave me more control at low speed.

"Atlas' new Dash 8-40CW would be a fine addition to a modern diesel roster. Two or three of these sharp-looking models would look great hauling a long intermodal train on a contemporary layout."