SD70M -

| SD75M | SD70M (Flared Radiators) |  |  |

| SD75I | SD70I |  |  |

SD70 -

SD70M -

| SD75M | SD70M (Flared Radiators) |  |  |

| SD75I | SD70I |  |  |

SD70 -

Introduced: 2005 (Korean-made SD70M / SD75M), 2006 (Korean-made SD70I / SD75I) and 2018 (Chinese-made SD70)

Apart from the shell variations, these Athearn SDXX units are all pretty much the same deal. So, to save myself a bit of time I'm going to cover them all here. Note that the original 2005 and 2006 releases were made in Korea by Ajin and that the more recent SD70 release was manufactured in China (by "whomever").

These are all very impressive models, and certainly right up there with the Atlases and Katos of the world. The paint and detailing are superb, as is the performance. However, there have definitely been some growing pains on the DCC-Readiness side of things. As explained in Ron Bearden's article (N Scale Magazine, May/June 2007), the early production runs of these models went through a rather bewildering series of DCC-related motor changes. To wit -

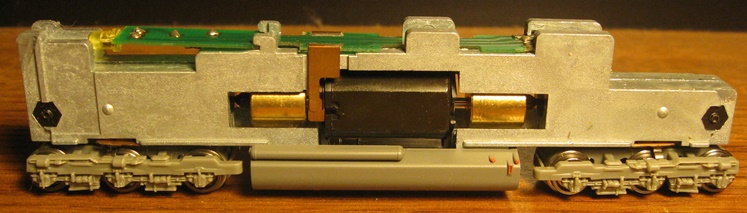

The earliest version had a 5-pole Mashima motor and skinny metal tabs running from the lightboard to equally skinny contacts on the motor -

This first version turned out to be a bit problematic in the DCC department (the design of the motor contacts apparently causing decoders to short out and fry). To address this problem, Athearn revised the lightboard-to-motor contacts and replaced the Mashima motor with an open-sided 3-pole motor with larger contacts (this particular version being limited to a very few SP units) -

And yes, this solved the decoder issues. Unfortuntely, it also caused the modeling community to freak out ("What happened to our 5-pole motors?!") So, Athearn re-revised the revised design, going back to the 5-pole Mashima motors but removing the lightboard-to-motor contacts entirely (instead, the contacts on the motor receive current directly from the frame) -

Sadly, this version wound up being out-and-out DCC-Hostile. So, Athearn opted to re-re-re-design things - this time combining the larger ligtboard-to-motor contacts of the 3-pole version, but going back to the 5-pole Mashima motors -

And yes, finally, it was this version that stuck. And I guess the upshot of all this is that if you're a DCC guy, you'll probably want to see the guts of your Athearn SDXX before buying it (at least if you're buying one of the early production models). Obviously some are a bit more "DCC-Ready" than others (decoder installation instructions from Athearn HERE)

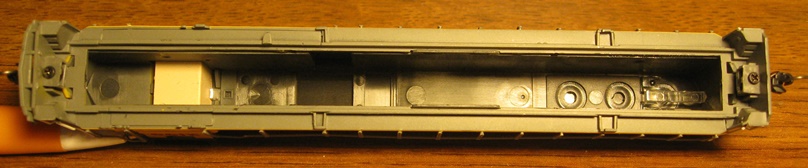

As for the common features, the chassis is all-metal and split-frame. Each motorshaft is equipped with a flywheel. Plastic driveshafts connect the flywheels to the brass worms. Said worms are mounted inside of bearing blocks that seat inside of notches in the frame. The headlight and backup light are directional (illuminated by two bright yellow/orange LED's on the lightboard). Unfortunately, the numberboards and ditchlights are not lit.

All six axles are geared and all gearing is plastic. There are no traction tires. The wheels are blackened and low-profile (no problems on Atlas Code-55 track).

All twelve wheels collect current. Pickup is "low friction" (IE needlepoint axles sandwiched between dimpled axle wipers). Extensions off the tops of the axle wipers rub against bronze contact strips attached to the bottom of the chassis. Collars on top of the truck gear towers clip inside of the chassis. The trucks pull off fairly readily, although I would suggest loosening up the chassis screws a turn or two before trying to do so.

Couplers are shell-mounted (Micro-Trains on earlier models and McHenry on more recent releases). All of these models have actual cab interior detailing (AFAIK, a first for mass-produced N scale plastic).

The shells are excellent looking, with fine paint and detailing -

As for other people's quibbles... Well, I've certainly come across numerous gripes about the thickness of the "glass" in the cab windows (the term "coke bottle" has been bandied about). Others have complained about the fact that some (or all) of the various shell pieces (shell details, walkways, handrails, fuel tank, etc) are glued together at the factory, making disassembly (for painting purposes) very difficult. Happily, not really a big deal for the "take it out of the box and run it" crowd.

Performance on these models is superb. Throttle response is nimble and they run smoothly and quietly at all speeds. They crawl along at the low end of the throttle in "one tie at a time" fashion (although the top-end speed is rather high). I can creep mine through turnouts with non-powered frogs without a hitch, so no problems with the pickup. Pulling power is impressive, with mine easily able to pull 30+ assorted 50' freight cars through curves on level track. I didn't have any problems with any of the wheels derailing (even on curves as sharp as 9.75" radius). Overall, these are great looking models that run extremely well.

Trivia - the difference between an SD70M and an SD70I (or an SD75M and an SD75I) boils down to one small shell detail - the I's have a seam on the shell between the cab and the nose. In the prototypical world, this was a bit of sound-dampening insulation that isolated the cab from the rest of the engine (hence the "I"). This served to reduce the racket inside the cab.

Features -

- Fully assembled and ready to operate

- Separately applied details like sunshades, snow plow, air horns and brake wheel

- Directional headlights

- Die-cast split frame design

- 5-pole motor with skew wound armature and dual brass flywheels

- All-wheel drive and electrical pick up

- Blackened metal wheels

- Magnetically operated knuckle couplers

- DCC-ready (maybe - see above)

Shell removal is blessedly simple (for the most part) - just grab the sides of the shell with one hand and the fuel tank with the other and then wiggle the shell up and off. I did find that the shell on the newer SD70 is a rather tight fit, and so had to insert a small screwdriver between the shell and chassis and then pry up and out on the shell in order to free it up from the bumps on the chassis. Once freed up, the shell pulls right off.

Grade: A (for all of 'em)

Reviewed: 12/05 Model Railroader ("Three modern EMD six-axle heavy duty freight locomotives, including two different SD70Ms and an SD75M are now available from Athearn. All three share a common design that combines superbly detailed plastic bodies with powerful, smooth-running mechanisms. The models come ready to run with isolated motors for conversion to DCC... These models closely follow the overall dimensions in prototype drawings, except for specific prototype variations. Athearn has done a fine job capturing the proportions and details of the various prototypes. Each body consists of a molded styrene cab, long hood, and a deck-and-pilot assembly. Most of the details are cast in place. The air horns, brake wheel, cab interior, railings, sunshades, and a snowplow are separate factory-applied parts that fit perfectly. The clear styrene window glazing has tiny wipers molded in place on the windshield. Clear styrene lenses are also fitted in the working directional headlights. The mechanism follows the split chassis design found in most N scale diesel models. Two small knobs are cast into each side of the metal chassis to secure the body. They're located above the middle axle on both trucks... A Mashima five-pole motor with a skew-wound armature and dual turned-brass flywheels drives both trucks through stand universal joints. Brass worms atop each truck tower drive all six axles through plastic spur gears. Electrical power is picked up with phosphor-bronze strips that run along each side of the chassis. All 12 drivers pick up current and transfer it to contact wipers above each sideframe. A PC board rides on top of the frame to collect and supply power to the motor and the directional headlight circuits... Both truck gearboxes are made of tough acetal plastic, and they're held together with interlocking latches. The distinctive EMD radial sideframes also snap into place. The wheelsets are blackened nickel silver and have NMRA RP-25 wheels that are mounted in gauge. Our samples locomotives started and ran steadily at only 1 scale mph. They operate smoothly and quietly through the normal operating speeds. However, the top speed of 160 mph is nearly double the prototype's maximum speed. Our samples came superbly decorated in accurate prototype paint schemes with sharp printed lettering. Athearn's new SD70M and SD75M locomotives are well made models of modern freight haulers that roam all over North America. CSX, NYS&W, NS, SP, AT&SF, BNSF. $99")