Introduced: 2007 (MRC decoder version), 2010 (Tsunami decoder version), 2013 (revised version), and 2017 (DCC-Ready version, NP Z-8, UP Greyhound)

This is one amazing locomotive, but then for $300+ I suppose it would have to be, eh? The detailing is pretty much off the charts (even as compared to some of the other finely detailed steamers of similar vintage available from, say, Bachmann or Life-Like). Better still, it's ready-to-run right out of the box - no "do it yourself" detailing required. Performance is similarly sublime. The gear motion is absolutely perfect - no wobbling, shimmying or shaking whatsoever. It pulls like an elephant and runs quiet as a mouse. Pick-up is perfect, throttle response is perfect, slow speed creep is perfect, and, well, the whole thing is just plain perfect.

Shell detailing varies by roadname -

UP Greyhound

SP&S / Northern Pacific Z-8

Clinchfield

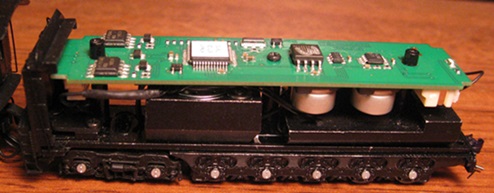

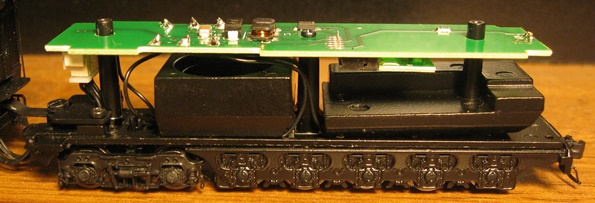

The chassis is all-metal and quite hefty. Up until 2017, the motor was an open-sided / skew-wound three-poler (which was a bit of false advertising on Athearn's part since they described it as having five poles in the manual). Starting with the 2017 production run, the motors were changed to actual five-polers. The motor driveshafts are each equipped with a flywheel. Four of the six drivers on each engine provide pickup. The forward drivers on the front engine are equipped with traction tires, as are the rear drivers on the back engine. All 14 tender wheels provide pickup. The pilot and trailing trucks are electrically neutral. Metal contacts conduct current from the drivers up through the engine towers. Wires soldered to the tops of said contacts then transfer current to a PC board mounted atop the chassis. Still more wires ferry current from the PC board in the engine back to the decoder board mounted inside the tender. The tender drawbar is screwed to both the tender and the locomotive. The wiring between the two is basically free-floating (and there's a lot of it). Fortunately, it doesn't seem to cause any problems (vis'a'vis derailing).

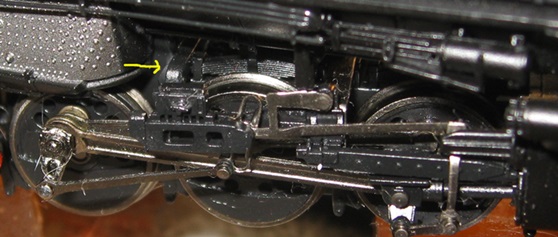

One driver pair per engine is geared (the ones with the traction tires). All gearing is plastic. A directional headlight is mounted to the pilot assembly (with long wires running back to the PC board on top of the chassis). Said light also provides illumination for the attached numberboards. A back-up light is mounted to the decoder board in the tender. A Micro-Trains coupler is mounted to the tender chassis. As delivered, there is no coupler on the pilot, however an ala-carte MT coupler for the pilot (to be installed by the modeler) was included with the earlier runs of this model (said coupler was eventually left out starting with the 2013 run). Both engines are articulated (pivot), consequently this model can run on curves as sharp is 9.75"-radius.

The first run of these models did not have low-profile wheels on the tender, the pilot truck and the trailing truck (they would rattle along on the ties of Code-55 track). Subsequent runs have had this problem addressed (IE, all wheels are low-profile).

| MRC Decoder | Tsunami Decoder | |

|  |

As noted above, these models originally came with MRC sound decoders. However, starting with the 2010 production run the decoders were changed to Soundtraxx Tsunami's. Operating the original MRC decoders on DC layouts required a special handheld remote (included with the locomotive). Conversely, the Soundtraxx decoders can be operated directly with a normal DC power supply. Thanks to the large/enclosed speaker, the sound on either version is quite impressive.

Note that at least some DCC systems have problems programming the MRC decoder. For example, my Lenz system is unable to read the feedback responses from the decoder when programming it on the programming track (something to do with the low current generated by the decoder when talking back to your system). So, when making changes you just kind of have to trust the digital gods that your changes are actually getting made, because your system is going to tell you that there isn't a locomotive on the programming track. Ultimately, I didn't have any problems making CV changes on mine, but it did take longer than normal (what with all the misleading error messages). As for programming "on the main", I couldn't get that to work at all... But again, this is a problem between certain DCC systems and certain sounds decoders and isn't a specific problem with this locomotive (per se). The good news is that my system has no problems at all programming the newer Tsunami decoder.

The first DCC-Ready version (IE no sound decoder) was released as part of the 2017 production run. As pictured below, the tender PC board on this version comes with a European-style six-pin DCC interface. It also includes the same speaker enclosure that comes with the sound-equipped models -

Overall, these are sensational locomotives - and certainly right up there with the all-time greats of N scale steam. My only real concern with them is their overall complexity. Given all that detailing, I get nervous just handling them. And although I'm pretty handy when it comes to tinkering with locomotives, I doubt there'd be much point in my even trying to work on one of these. Just taking the shells off in order to take pictures of the internals was a somewhat daunting task. Unless you're some kind of mechanical genius, I'd suggest leaving the repairs to Athearn.

Note - Athearn eventually decided that their original tender drawbar design was too complex (making it extremely difficult for their service department folks to disconnect and reconnect the tenders when working on these models). Consequently, the drawbar was redesigned with the 2013 release. The original version had sprung "V" mounts on both ends, whereas the new version has a simple loop on the locomotive end -

Unfortunately, at least some of the 2013 Challengers were delivered from the factory without the required spring on the "V" end. Said spring connects to a notch in the drawbar and loops around the post behind the drawbar -

Without the spring to center the drawbar, the tender tends to ride down the rails a bit crookedly. The good news is that the Athearn parts department is (as of this 2013 writing) supplying replacement springs to those who ask for them. However, the installation of said spring is a rather complicated procedure, so if you're not comfortable with the idea of tearing your tender apart you might want to just send yours in to Athearn for repairs.

In addition to the drawbar changes, the headlight in the 2013 run was changed from an incandescent bulb to an LED. Also, a plastic brace was installed behind the valve gear framework to keep it from squishing in and fouling the main rods when handling the locomotive (apparently a source of numerous returns on earlier runs) -

Note on the 2017 production run - I've read various reports of rampant QC problems with the 2017 production run of Challengers (bad wiring, bad soldering, bad assembly, poorly fitting parts, etc). And although I did not order one from that production run myself, I did have a lot of problems with a 2017 Big Boy. So, I dunno what that all means? Maybe Athearn switched Chinese factories and the new one isn't as good as the previous one. In any case, let "try before you buy" be your watchword (if possible).

Here's what Athearn has to say about them -

Era: 1940's to 1980's

The N Scale 4-6-6-4 Challenger includes a history book and instruction book for quick reference. This stunning reproduction of the 4-6-6-4 Challenger is the result of a focused determination to accomplish one thing: create the finest operating miniature representation of the prototype available.

Giving life to all the details are authentic sounds that are channeled through a factory installed DCC and soundboard with speakers. The DCC decoder automatically senses what type of power supply is in use (conventional DC or NMRA compliant DCC) and adapts its functions. The modeler doesn't have to do a thing.

Functions and sounds available to DCC users include -

- Bell

- Whistle

- Water injector

- Air release

- Blower hiss

- Fire box door

- Lighting direction but

- Coupling

- Brake squeal

- Conductor's voice

- Sand release

- Cylinder cock/flange squeal

A handheld wireless controller is included with the MRC version for use with conventional DC power supplies. With it, modelers can control six sound functions as well as speed and direction.

Key Features Include:

- Boiler backhead with full detailing

- Individually applied piping, valves, generators, etc.

- Correctly operating eccentric cranks

- Pivoting front and rear engines for negotiating 9-3/4" radius curves

- Factory installed onboard sound and DCC decoder

- Hand held remote control for DC operation (MRC version only)

- Blackened metal wheels

Trivia - For those interested in running their Challenger with UP water tenders (either pre-rebuild or post-rebuild), James Norris (JamesTrainParts) sells them through his Shapeways store -

Grade: A (although a potential "F" for a large portion of the 2017 production run)

Reviewed: 06/07 Model Railroader ("For N scale fans of big articulated steam locomotives, what's more exciting than a 1:160-proportion Challenger 4-6-6-4? How about one equipped with realistic onboard sound. The Challenger is the first DCC-and-sound-equipped N scale steamer in Athearn's product line. The model's dual-mode decoder, manufactured by MRC, provides controllable sound effects on both DCC and DC layouts... The N scale model matches all the prototype's dimensions with discrepencies similar to those found on the HO version... The pilot wheels are 34 scale inches in diameter instead of 36", and the drivers are 67 scale inches instead of 69"... All lettering and decoration is crisp and straight and matches the prototype... Separately applied details include handrails and a plated whistle and bell. Molded-in details such as rivets and boiler-bands, match prototype photos. The tender correctly includes an oil bunker with modern safety appliances that were added after the year 2000... The model has the correct full enclosed all-weather cab with front, rear, and side window glazing. The interior has no figures, but the backhead does have gauges and other detailing. The pilot has a swing-out coupler pocket so that you can attach the included front knuckle coupler that mounts at the correct NMRA height. The model has the correct twin smokestacks of the prototype, but a noticeable black Phillips screw is used inside the front stack to attach the boiler to the chassis. The prototype's smokebox has a shield-shaped number plate, but unlike the prototype the shield on the model is blank. The engine and tender are connected by a permanent drawbar and wires. As noted in the instructions, disassembly of this locomotive by the user isn't recommended.

The motor is inside the boiler and drives both the front and rear driver sets through separate worm gears and gearboxes. Both the rear drivers of the rear engine and the front drivers of the front engine have rubber traction tires, contributing to the model's above-average drawbar pull (50 cars)... The blackened metal cranks and rods are realistic. The eccentric cranks are also oriented in the proper direction so that they lean forward when the main rods are in the bottom center position. On prototype Challengers, only the front engine swivels. On the model the rear engine also swivels, allowing it to negotiate a curve with a radius as tight as 11"... Sounds and lights on the model come on at 3 volts. In DC, The Challenger starts moving on 8 volts at 2 scale mph. The model's top speed was 64 scale mph at 12 volts. In DCC, we tested the Challenger with a 12-volt power supply as specified in the instructions. Using 128 speed steps, the model crawled in step 4 at 3 scale mph. Our sample reached a top speed of 79 mph in step 128... A six-button remote control allows you to trigger certain sound effects and control the Challenger's speed in DC operation... Along with the whistle and bell, other sound effects controlled by the handheld remote controller include the sound of the water injector and the conductor yelling "All aboard!" Using the remote you can program some sound effects, including the whistle type. These range from a deep steamboat-style whistle to a high-pitched single-chime whistle to a few other options in between. The whistle is the weakest sound effect of the model... The engine's exhaust rate is adjustable in DC or DCC, but the model came programmed with the correct 4 chuffs per wheel revolution, and the sound was synchronized with each engine. In DCC, most of the model's sound and performance features are programmable. A CV table is included in the instruction manual. The overall sound quality is impressive for a 1:160 model. The speaker is well-enclosed without any distracting buzzes or rattles. With its high level of detail and onboard sound, the model brings a new level of realism to N scale. $424.98