U25C -

U28C -

U25C -

U28C -

Introduced: 2015 (U25C) and 2016 (U28C)

Arnold's gorgeous looking and fine running U25C model represented the return of the Arnold brand to North American N scale. And what a long, strange trip it's been! One of the pioneers of early N scale, Arnold-Rapido (Germany) was purchased by the Rivarossi Company (Italy) in 1997. Arnold's products lived on for a time after that (marketed under the "Arnold-Rivarossi" label), but were eventually mothballed when Rivarossi went bankrupt and was subsequently purchased by Hornby Railways in 2004.

Hornby has since revived some of the old brand names they'd acquired over the years - using them to differentiate the various scales they sell (HO models marketed under the Rivarossi label, N scale models marketed under the Arnold label, etc). And although Arnold/Hornby still sells some of Arnold's original European models, the old Arnold/Rivarossi line of North American prototype models has apparently been retired (not surprising since they'd all be fairly primitive by modern standards). Consequently, the all-new U25C was the very first North American N scale model to be marketed under the Arnold/Hornby banner.

As noted above, Hornby followed up their 2015 U25C release with a new U28C model in 2016. The two models share identical internals (and apart from some minor variations in the detailing, identical shells as well).

These models sport some of the finest paint and detailing ever rendered on an N scale diesel - thin window glazing with scale gaskets and wipers, numerous see-through and etched parts, scale MU cables and cut levers, and just about the skinniest handrails I've ever seen -

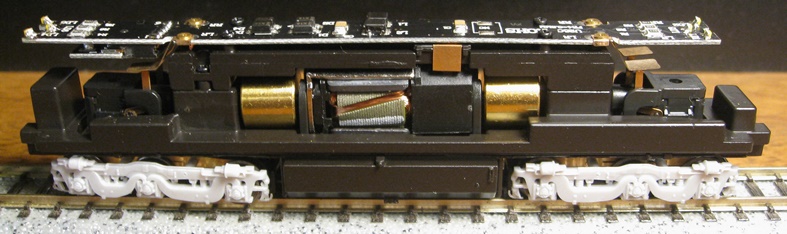

Internally, these models are quite a departure from the standard split-frame mechanisms we're used to seeing from the likes of Atlas and Kato -

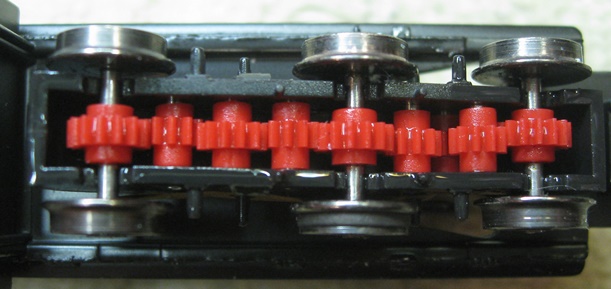

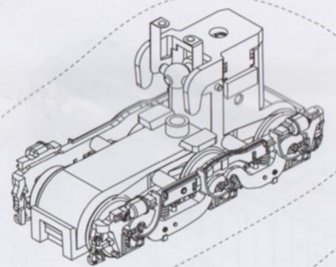

The chassis consists of a large metal base that holds the five-pole / skew-wound motor and dual flywheels. A smaller metal bracket screws to the top of the base, thus holding everything together. Pickup is provided by wheelback wipers. Said wipers have lengthy extensions that protrude up through the truck towers and ultimately brush up against flexible contacts extending down from the lightboard. Contacts from the lightboard route current to the motor. Plastic driveshafts (with U-Joints) run between the flywheels and the worms. Said worms are seated inside bearing blocks (with the entire worm assembly then mounted inside the truck tower).

A European-style six pin DCC interface is provided on the underside of the lightboard. And wow, is the lighting ever interesting! There are actually three individual LEDs on each end of the lightboard (one for the headlight/taillight and two for the numberboards). And under this scheme, the headlight and taillight are directional, whereas all the numberboards remain lit regardless of direction. Quite an innovation!

Five wheels per truck provide pickup (with the remaining wheels being equipped with traction tires). The metal fuel tank is screwed to the underside of the chassis, providing additional heft -

All six axles are geared and all of the gearing is plastic. The wheels are low-profile, so no problems on Code-55 rails -

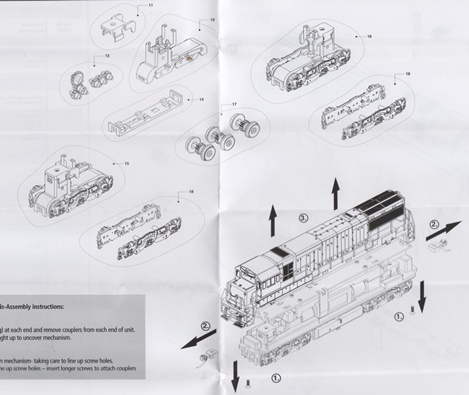

Each truck is held to the chassis by a plastic push-stud inside of the truck body (pushing up through the collared hole pictured below and into a hole in the chassis) -

The couplers are all-new as well, being similar in style to Micro-Trains (right down to the annoyingly microscopic centering springs). However, size-wise they are more akin to Accumates -

Performance on these models is absolutely outstanding in every way. Mine runs super smooth and whisper quiet at all throttle levels. It can creep along one-tie-at-a-time at the low end of the throttle, whereas the top-end speed is quite realistic. Pickup is flawless (despite the traction tires), with mine able to successfully creep through insulated-frog turnouts at extremely slow speeds. Owing to the heavy metal chassis (not to mention the traction tires), mine can pull 40+ assorted 40' freight cars on level track like they're not even there. On the downside, 11" is pretty much going to be your minimum radius for curves when operating one of these (mine consistantly derails on 9.75"-radius curves).

OK, I do have a few minor quibbles. First off, yes, I love the skinny handrails. However, I can't say that I'm entirely thrilled with their implementation. As delivered, it is virtually impossible to handle one of these models without dislodging half of the stanchions from the sidesills in the process. So, if I were going to be running one of these guys on any sort of regular basis I would go ahead and apply a bit of white glue to the stanchion nubs in order to get a firmer and more permanant grip. Next up - traction tires. Um, why? My gosh, this thing weighs a ton. Were they really necessary? I mean, no, they're not a problem at first. But sooner or later they will be, so why even go down that road? Lastly, I find the shell removal procedure to be a bit annoying. To get the shell off, you first have to unscrew and remove the couplers. And unfortunately, said couplers tend to fall apart into a million little pieces if you're not careful how you handle them (don't ask me how I know this).

Still and all, let us not end this review on a negative note. Minor gripes aside, these are flat out gorgeous looking models that perform every bit as good as they look. Definitely an auspicious beginning for Arnold/Hornby in North American N scale, and I look forward to more releases from them.

Here's what Arnold/Hornby has to say about them -

Hornby America is pleased to announce the return of Arnold N scale to the US model railroad marketplace. The first new release in the re-introduction of Arnold N scale will be the General Electric U25C diesel with all new state-of-the-art tooling! Arnold has long been associated with the production of high quality N Scale and is now the latest addition to the Hornby America model railroad line-up.

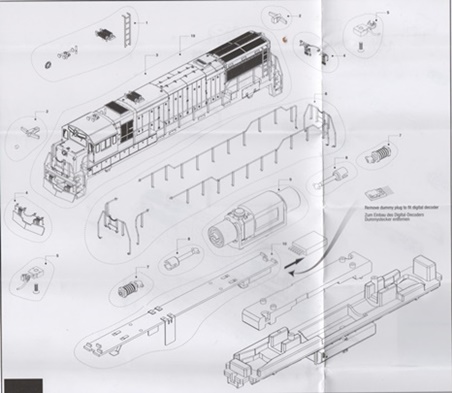

The new model of the U25C has been licensed by and developed with full co-operation of the Transportation Division of General Electric. Multiple roadnames and roadnumbers will be available for the new model and will incorporate all new state-of-the art tooling with the following features -

- Heavy metal die-cast chassis

- Five-pole motor with flywheels

- State-of-the-art power pickup

- Locomotives will have road specific detailing

- Detail parts: horns, bell, handrails, grab irons and snowplows (if applicable)

- DCC Ready configuration to accept standard NMRA 6 pin decoder

The GE U28C was the company's second six-axle model it produced and was virtually identical to its predecessor, the U25C, save for a slight increase in horsepower. The GE U28C began production directly after the U25C in December, 1965. It was all but identical to its predecessor (for instance it was the same length and weight and featured the tri-mount truck standard on many early GE C-C models) save for the slight increase in power to 2,800 horsepower using GE's 4-cycle model FDL16 prime mover. All the common attributes of early GE diesel locomotives were present in the U28C such as a standard/plain carbody design, short, low nose and relatively good reliability. Its tractive effort was slightly higher than the earlier U25C with 92,500 pounds of starting effort and about 79,500 pound continuous.

As noted above, to remove the shell you first have to unscrew and remove the couplers. The shell should lift right off at that point.

Grade: A

More good news - the box includes a full-blown parts list and assembly diagram. Remember the good ol' days when that used to be the rule rather than the exception??