Introduced: 2015

These gorgeous looking and smooth running switchers were Arnold-Hornby's second North American N scale locomotive release (following closely on the heels of their 2015 U25C release). They are available in a number of different detailing packages (depending on the prototype in question). Variations include cab-front windows, cab-top beacon, headlight, horn, sidesill handrails, sidecab window shades, trucks (and probably a half dozen other things I've missed).

The finely detailed plastic shell consists of three separate / clipped-together parts (hood, cab and sidesill).

The couplers are screwed to the underside of the sidesill -

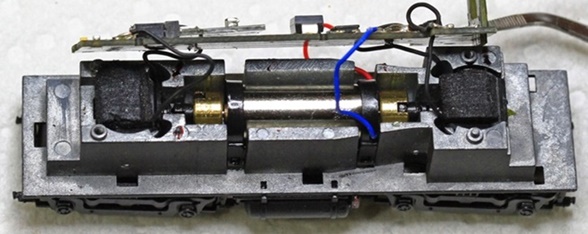

Internally, the locomotive chassis is a one-piece metal casting. A DCC-Ready PC board is screwed to the top of the chassis. Directional lighting is provided by bright white LED's (mounted to the board itself on the front end, and to a plastic tower on the cab end). A standard European 6-pin "NEM 651" DCC interface is provided on top of the board. Wired wheelback wipers transfer current from the trucks to the PCB (two wires per truck). A second set of wires transfers current from the PCB to the motor -

The flywheel-equipped motor is a closed-sided can (and presumably coreless). Plastic dog-bone style connectors link the flywheels to the worms. Said worms are seated inside of bearing blocks (with the entire worm assembly then mounted inside the swiveling truck towers). Plastic clips on top of the truck towers hold the trucks to the chassis -

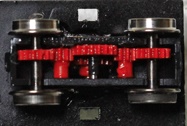

Three wheels per truck provide pickup (with one wheel per truck being equipped with a traction tire). Plastic fuel tank details are press-fit to the underside of the chassis. All four axles are geared and all of the gearing is plastic. The wheels are blackened and low-profile (no problems on Code-55 rails) -

The couplers are the same as those found on the U25C (and proprietary to Arnold). They are similar in style to Micro-Trains couplers (right down to the annoyingly microscopic centering springs). However, size-wise they are more akin to Accumates -

Performance-wise, mine was a little balky at first, but I'm going to assume that this was due to some sort of factory crud on the wheels (either lubrication or blackening "stuff"). In any case, after hooking up a track cleaning car and then highballing it around for a few minutes, performance smoothed right out.

Once suitably broken in, performance is breathtakingly flawless. Despite the traction tires, pickup is perfect (even creeping through insulated-frog turnouts). Mine runs super smooth and whisper quiet at all throttle settings. It can creep along almost slower than the eye can detect at the low end of the throttle, whereas the top-end speed is nicely prototypical for a yard switcher (IE, quite low). And my gosh, you want pulling power? I hooked mine up to thirty assorted 40' freight cars ('cuz that's what I happened to have sitting on the track at the time), figuring that I'd have to start pruning cars off in bunches in order to find the engine's upper limit. But nope, it hauled those suckers away like they weren't even there!

One small problem that I did encounter was with the couplers. Initially, I was having just one heck of a time getting the loco to snag an MTL-equipped car and pull it away. And after eyeballing things a bit, I noticed that the couplers were very "sticky" (IE, they didn't readily re-center themselves). The problem here turned out to be overly tight mounting screws, and after loosening them up a half-turn (or so), the couplers descrunched and started operating much better. But that said, the claws are still awfully small (as compared to MTL's) and getting an automatic connection can sometimes take a couple of tries.

As for replacement options, MTL Z scale couplers (#905) are reportedly pretty close to being a drop-in option (you just have to file a little bit off of the back of the coupler boxes to give the trucks room to pivot). MTL 1015's are also an option, but you have to use the Arnold coupler boxes and just swap out the internal coupler "guts" (the 1015 box is too big to fit in the available space). Additionally, you have to shorten the little plastic post that sticks up on the loop portion of the 1015's upper shank (as is, it's too tall to fit comfortably inside the Arnold coupler box and will get hung up on the lid, thus preventing the coupler from centering properly).

Here's what Hornby has to say about these models -

Hornby America is pleased to offer the "pure classic" EMD SW-1, a model long requested by N scalers. Please note the many variations - no two locos are the same and all detailing is documented by prototype pictures. You are witnessing the beginning of prototype-specific detailing in N scale. These units are DCC-Ready (equipped with an NEM 651 6-pin socket), and accept the readily available TCS EUN 651 decoder. This is a LIMITED RUN OFFERING (MSRP $129.99).

Prototype Info -

The EMD SW1 is a 600 HP diesel-electric switcher built by General Motors subsidiary, Electro Motive Corporation; subsequently renamed Electro Motive Division; between late 1938 and late 1953. As with most long-running locomotive production models, many revisions/upgrades were made during the course of production. A very noticeable change was in the shape of the two windows located in the front of the cab; originally curved to follow the roofline, they were changed to a flat top in the mid-1950 to simplify the manufacturing process.

Along the same lines- the two stage taper used in the construction of the hood in front of the cab became a simpler, less costly single stage taper in later production. The very early production units had a minimal exhaust stack, but in operation this left much to be desired as the exhaust would spew directly back toward/into the cab (impairing crew visibility). These early units were railroad-modified with welded-on extensions, whereas later production would come with EMD's trademark conical switcher stack. Depending on production dates and railroad modifications, numerous headlight configurations were possible.

Model Features -

- Horns, bell, and handrails

- 5-Pole can motor with flywheels

- DCC-Ready (standard NMRA 6-pin DCC interface)

- All-wheel drive

- Heavy metal die-cast chassis

- Road-specific detailing

- State-of-the-art power pickup

Shell removal is pretty simple. Basically all you have to do is grab hold of the fuel tank with one hand and the shell with the other and then wiggle the shell up far enough to put some daylight between the sidesill and the chassis "lip". Then, use a small screwdriver between the shell and the lip to pry/slide the shell up and off. Note that the cab-end LED tower has a little plastic shroud press-fit around the LED. Said shroud is prone to popping loose and obscuring the LED, so if you put the shell back on and the rear light doesn't light anymore, that's what happened.

Grade: A (if you don't mind the couplers)