Introduced: 1996 (first run AMD-103 and B32-8P-DM), 1998 (P42DC), and 1999 (second run AMD-103)

Looks-wise, these models are all nigh identical. And internally, they're all branches on the same evolutionary tree. So, to save myself a bit of time I'm going to go ahead and cover them all here.

The 1996 AMD-103 / B32-8P-DM release marked a new beginning for the Overland/Ajin partnership (their only previous collaboration having been their one-off DD40AX in 1983). And since that time, the two firms have combined on numerous brass locomotive releases of respectable quality. Unfortunately, these early GE diesels wound up being a bit of a mixed bag.

As is generally the case with brass, the looks are top-notch. The factory-painted brass shells are quite exquisite and include a lot of details not normally associated with brass (window inserts, directional lighting, and Micro-Trains couplers to name three). Sadly, it's the actual mechanisms where the skies start to get cloudy.

The first-run AMD-103 and B32-8P-DM share the same chassis/mechanism - one described to me by Brian Marsh (Overland's president) as being "a major mechanical frustration" -

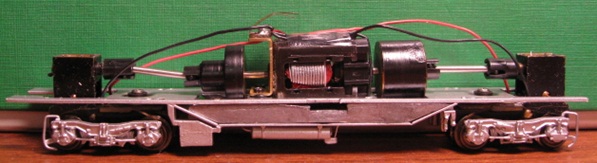

The chassis is simply a flimsy brass rectangle. The motor is a closed-sided can (and presumably 3-pole / straight-wound). There are no traction tires, so all wheels collect current (by way of really chintzy looking wheel-top wipers). Wires soldered to each wiper transfer current to the motor and the lighting mounted inside the shell. Said light wiring employs plug/socket connectors, allowing one to completely separate the shell from the chassis. The driveshafts are multipiece plastic affairs (with, as pictured above, a skinny flywheel on one side). Wheels are low-profile, so no problems on code-55 rails.

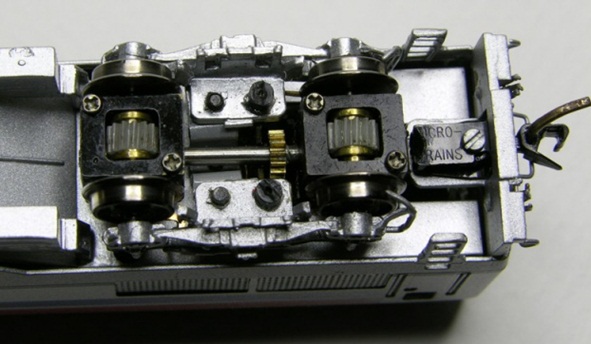

The easiest way to identify this early version is by its trucks. This first design employed a complex scheme that involved a secondary driveshaft inside each of the trucks (to turn the axle gears) -

Performance on this first version is mediocre at best. First off, they're quite noisy (no doubt owing to that overly complex driveshaft/gearing scheme). Overall running is a bit jittery and uneven, with out-and-out stalls being fairly common. I suspect that those wheel-top wipers are the culprit here, however accessing them in order to clean and adjust them does not look to be a simple task, so I was not able to verify that theory. Lastly, mine has serious problems maintaining any sort of constant speed through curves. In fact, I've had mine flat out come to a halt when trying to go through curves at slow speeds. Applying more throttle will get it going again, so apparently it's a mechanical (as opposed to electrical) issue. But whatever the case, these models simply do not run well enough to be considered "operable".

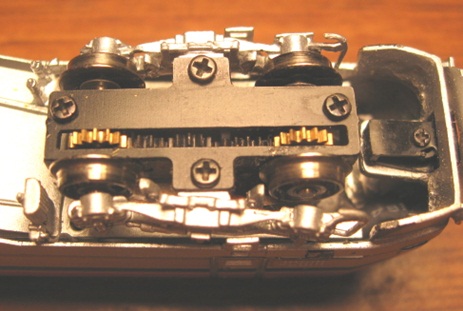

The second-run AMD-103 and the P42DC received new and improved internals. Overland also sold these new power chasses ala carte for people who wanted to upgrade their earlier models. The revised mechanism is an improvement over the original, although it's still fairly primitive by more modern standards. Once again, the chassis is all-metal and fairly minimalistic (with the brass shell providing most of the locomotive's actual heft). As on the first version, all wheels provide pickup via wheel-top wipers, with current transferred to the motor by four separate wires. The motor is a skew-wound 3-poler that spins dual flywheels (one large and one small) on simplified metal driveshafts. Metal contacts on the motor-mount bracket replace the lighting wires of the first version.

The truck design is a more traditional one (lacking the secondary driveshafts of the earlier version). All wheels are geared, with the gearing being a mixture of plastic and brass -

Unfortunately, it's the motor mount where I've run into problems with these redesigned models. That single flimsy bracket is the only thing holding the entire motor assembly to the chassis. And since there is a huge open space underneath said motor, said assembly is basically free to move around wherever it wants to.

As you can see from the above picture, the motor in my second-run AMD-103 came mounted "a tad askew" (to say the least), causing one of the driveshafts to be pitched at a scarily steep angle. And suffice it to say, the thing screamed like a banshee when it ran. So, I spent a bit of time adjusting the motor this way and that (remember, it's completely free-floating), and eventually got the driveshafts about as straight as they were ever going to get (not without more serious modifications anyway). And although it did wind up running a bit smoother and quieter than previously, it still made a hell of a lot of noise. Well, no surprise there. With all of the various parts pointing every which way and vibrating like mad, who can blame them for being noisy?

On the other hand, I have a P42DC (same mechanism) that appears to have been assembled correctly - exhibiting none of the noisiness of my AMD-103. Rather, its problem seems to be a basic inability to maintain any sort of constant speed - particularly when moving through curves at the low end of the throttle, where it always wants to slow down (shades of the first version here).

So, as mentioned above, these models are definitely a mixed bag. Yes, they look great, they're stronger pullers, and the revised mechanism is at least capable of running smoothly and relatively quietly. However, getting to that point is likely to require a bit of tinkering first. And in a world where we have Kato's vastly superior P42 model, I'm not sure why anyone would bother.

To remove the shell, unscrew the four tiny screws holding the chassis to the shell (two on either side of the fuel tank). The shell should pop right off at that point.

Grade: C (for all)